BigAl

Gone But Not Forgotten

Taking a quick lunch break . The snap rings are now in place !!! I revised the snap ring pliers and talked the little woman into helping hold the back side of the ring in place . Worked slicker than hell !

I revised the snap ring pliers and talked the little woman into helping hold the back side of the ring in place . Worked slicker than hell !

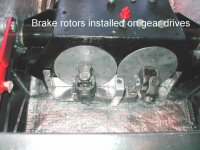

I am now reattaching the track rails in place after lunch . Sure wish their was a chrome shop close by ,and I would have the bogie wheels done in chrome as a custom look . Maybe later . Lots of pictures tonight !

I revised the snap ring pliers and talked the little woman into helping hold the back side of the ring in place . Worked slicker than hell !

I revised the snap ring pliers and talked the little woman into helping hold the back side of the ring in place . Worked slicker than hell !I am now reattaching the track rails in place after lunch . Sure wish their was a chrome shop close by ,and I would have the bogie wheels done in chrome as a custom look . Maybe later . Lots of pictures tonight !

,

,

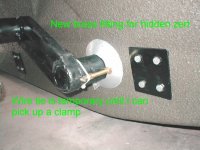

. I can also insert a 3 ½ “ snap ring in a 1” hole if necessary

. I can also insert a 3 ½ “ snap ring in a 1” hole if necessary  !

!