Track Addict

Bronze Member

Material on the way to replicate the pivot bushings. Going to bush the piston clevis back with steel and use a bronze clevis. Should have done this on the 73 in hindsight and probably will.

Set the pivot in place to figure out what to add back from wear. Need to add 1/16 to the face so that collar was around 1/4" give or take Tucker tolerance.

The pivot was mounted in the frame out 3/4" one side to the other. I checked the measurements front back all over and it's set oem like that. Mounting it back this way by design or eyeball fabrication because it worked. I like to believe this is by design so that is what we will go with.

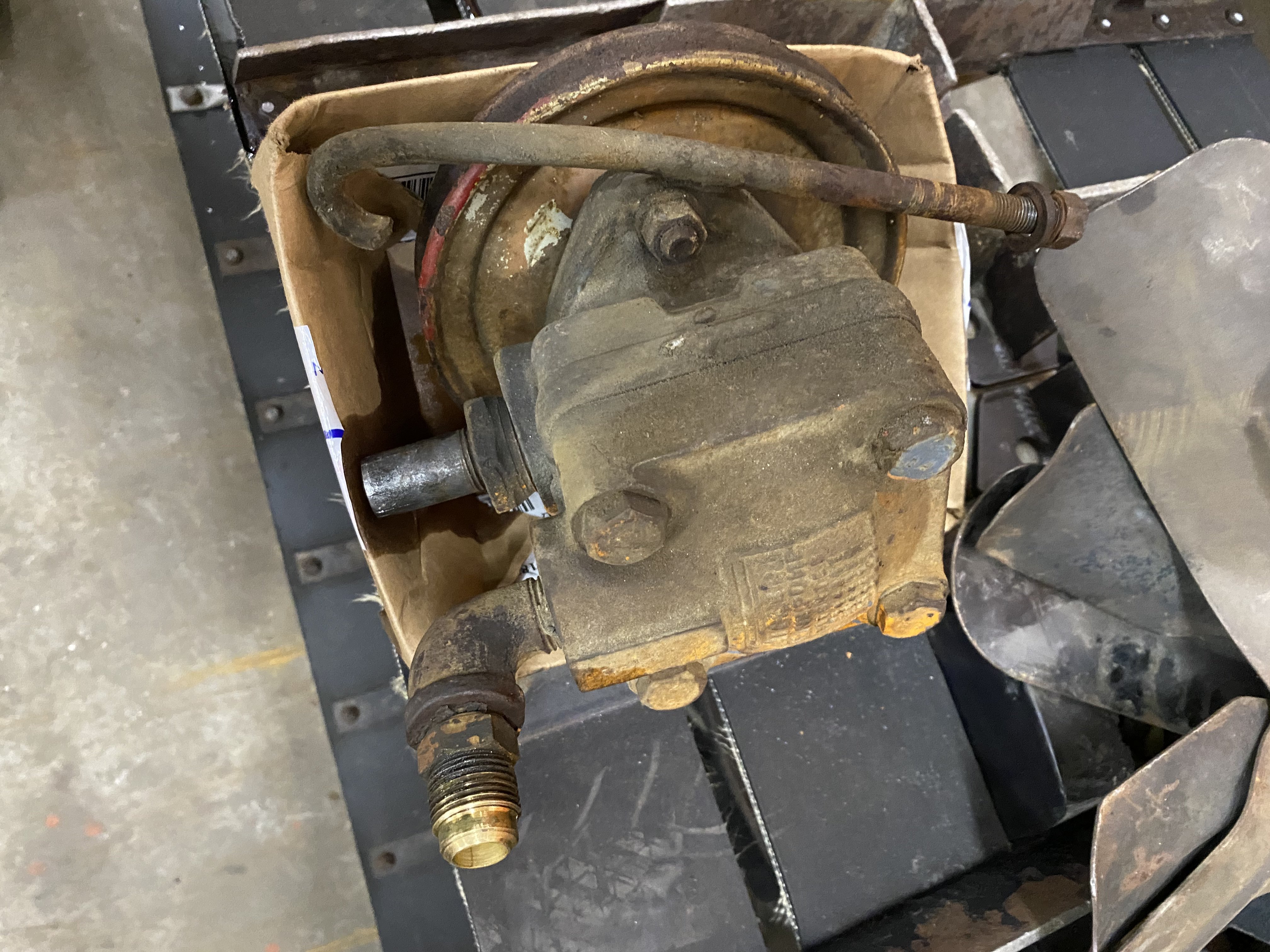

Hydraulic pump adjuster here to stay. Actually pretty neat design. Will add a sleeve in the tube where the bracket mounts to keep the tube from colapasing and stabilize the frame.

Note the black pipe nipple on the pump suction tube still complete with chop saw slag inside.

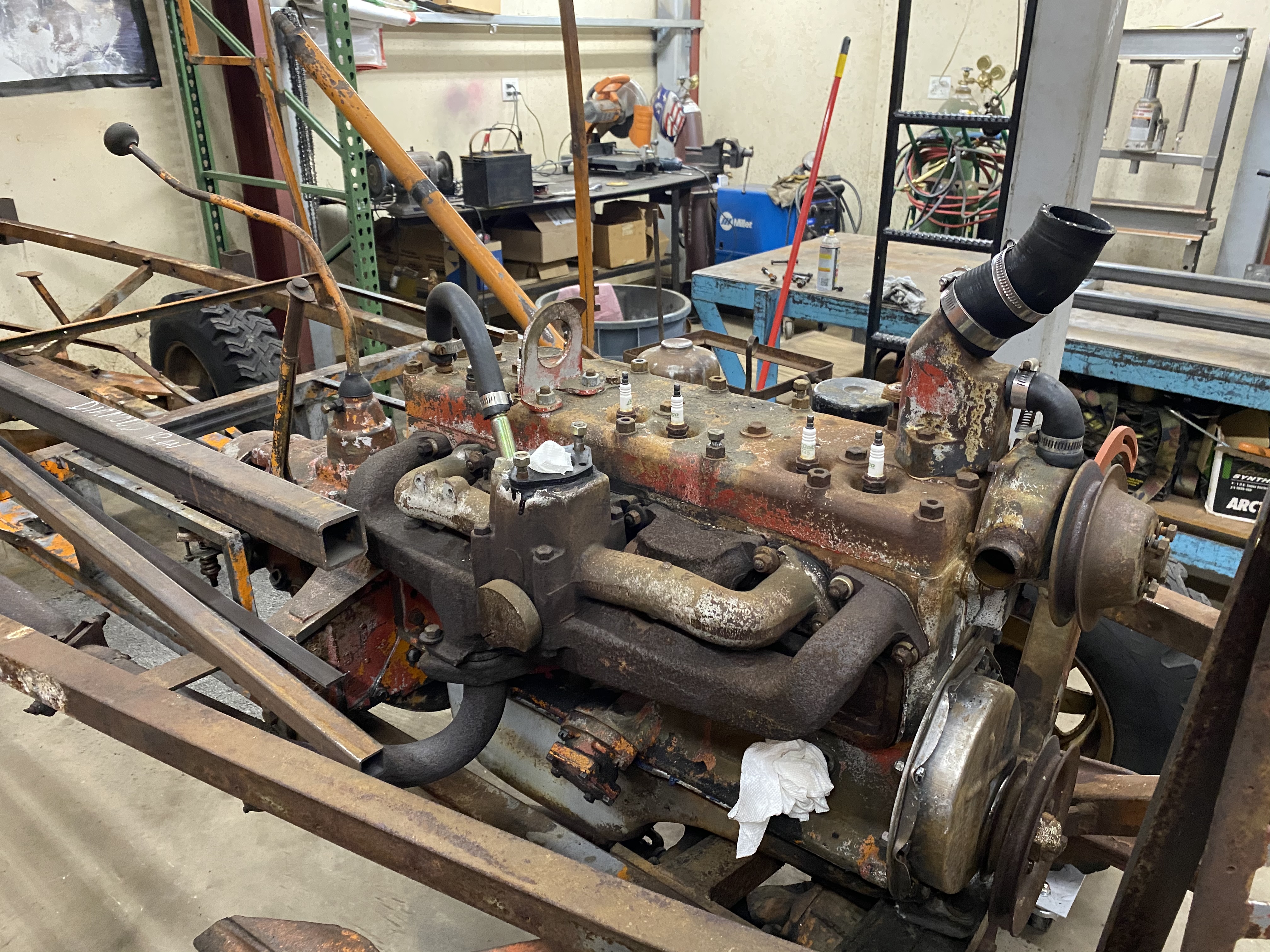

Motor ready to pluck!

Set the pivot in place to figure out what to add back from wear. Need to add 1/16 to the face so that collar was around 1/4" give or take Tucker tolerance.

The pivot was mounted in the frame out 3/4" one side to the other. I checked the measurements front back all over and it's set oem like that. Mounting it back this way by design or eyeball fabrication because it worked. I like to believe this is by design so that is what we will go with.

Hydraulic pump adjuster here to stay. Actually pretty neat design. Will add a sleeve in the tube where the bracket mounts to keep the tube from colapasing and stabilize the frame.

Note the black pipe nipple on the pump suction tube still complete with chop saw slag inside.

Motor ready to pluck!