What are you going to do about the transfer case, drive lines axels and differentials that were designed for about half the power you are going to throw at it. I sold a 442 last year and the first thing the new owner did, was freeze the tracks down and twist one of the front axles off, with a flat six.

-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Snowzilla": A Comprehensive Tucker 1643 Project...

- Thread starter Blackfoot Tucker

- Start date

What are you going to do about the transfer case, drive lines axels and differentials that were designed for about half the power you are going to throw at it. I sold a 442 last year and the first thing the new owner did, was freeze the tracks down and twist one of the front axles off, with a flat six.

That’s a good question. However, the new owner of your 442 committed one of the cardinal sins of snowcat operation, and learned a lesson the hard (expensive) way. Letting the tracks freeze to the ground is a major no-no, as is turning the steering wheel when the tracks aren’t turning.

The engine in Putri-Zilla is a GM L94 6.2 Liter LS series engine, very similar to the LS3 used in the Corvette. Its displacement is 376 cubic inches and its rated torque output is 417 pound feet at 4,300 RPM. Putri-Zilla came with a Chrysler 318 Industrial engine. I don’t have the specs for the 318, but it’s slightly bigger brother, the 360 Industrial, was rated at about 270 pound feet at 2,400 RPM. So the L94 puts out about 55% more torque. However, when it's done Putri-Zilla will be used for cabin access in Southwestern Colorado; at an elevation of 8,000-10,000 feet. (Note: I’ve been there and it is spectacular country!) As a normally aspirated engine, it will lose between 24-30% of its power at those elevations. A 24% haircut off 417 brings you down to 317 foot lbs, which unfortunately is only about 50 pound feet more than a 360 Industrial at sea level. At 10,000 feet the 30% power loss brings the L94 down to 292 pound feet; just over 10% more than the 360 Industrial at sea level.

Prior to starting on Putri-Zilla we built and tested our Thundercat project, which has the GM L18 engine, aka: the 8.1Liter Vortec. 8.1 Liters equates to 496 cubic inches and that’s a big motor! GM designed this engine as a "torque-a saurus”; a much cheaper alternative to the costly Duramax. It produces 455 pound feet of torque at 3,200 RPM. That’s actually a tad more more than the somewhat legendary 5.9 Liter Cummins 6BT Diesel. But, the Cummins is turbocharged and the 8.1 is normally aspirated.

I think people are under the mistaken impression we are trying to increase the top speed on our Tucker projects, but that’s not the case. Foot to the floor on Thundercat, on a flat groomed trail I think we hit 18 MPH. It is not a comfortable 18 MPH, either. Tracks are throwing snow everywhere. As a 1600 series machine, each long track assembly has 31 steel grousers which weigh about 9 pounds each. With four tracks that’s just over 1,100 pounds of rotating mass, and that number doesn’t include the rubber belts. At that speed the huge rotating mass makes things a bit uncomfortable. Yeah, you can do it, but if a grouser (for example) comes loose, it could do a lot of damage. The extra power in the GM engines really allows you to operate in a higher gear at less than full speed. They also start more easily and are more efficient than the stock carbureted Chrysler Industrial engines.

I’m sure you’ve heard the term “non-destructive testing”. Scott doesn’t really believe in that. His theory is if it’s going to break - he wants to know about it, so we can address any deficiencies now rather than later. When we tested Thundercat, we wailed on it pretty hard. It is true Thundercat left the factory with the optional heavy duty transfer case and Putri-Zilla has the standard transfer case, but we think it's more than adequate. Thundercat got a 12” frame stretch, which moved the rear axle back 12”, and we moved the front axle forward 2”. That meant two new driveshafts and it has new Spicer U-joints. Putri-Zilla’s driveshafts were in fine shape, but it too got new Spicer U-joints. Both machines are equipped with Dana 60 axles with 4.88:1 ring and pinion gears and we installed Eaton E-Locker selectable locking differentials in the front and rear axles on both machines.They are also equipped with Allison AT545 four-speed, non overdrive automatic transmissions. Operating on snow as opposed to asphalt has quite a bit of “give" that asphalt doesn’t, and the torque converter in an automatic transmission will slip a bit as opposed to gears which are a positive mechanical connection. But at the end of the day if something breaks, we’ll try and figure out why and upgrade the problem component. Part of the fun for us is improving a product based on our research and putting that research into action in the form of the conversion. In my experience, no matter how carefully you research the topic, you WILL be confronted with unexpected challenges.

It’s too bad these power train conversions are so expensive and so much work because we think the modifications are very worthwhile. Both project Tuckers were built about 40 years ago and in that period the automotive world has benefited greatly from numerous innovations. We think swapping a newer generation engine into a vintage Tucker brings with it a level of refinement that is very welcome.

Snowy Rivers

Well-known member

Yessssss....Engineering is great....Design is great.....Take it out and let bubba flog it....BETTER..

I wouldn't put a diff lock on it for sure

I’m not sure why….

I recall a conversation with the late Bill Guthrie who told me of a blade-equipped Tucker that was used at a sugar beet processing facility somewhere in Idaho. They used it to climb piles of sugar beets and to move them around. Bill said that with the locking differentials it was more or less unstoppable. In conversations with Jeff Godard at Tucker, Inc we discussed selectable lockers. He said Tucker has used both the ARB air lockers and the Eaton E-lockers. They preferred the E-lockers to the ARB units as they experienced some air line freezing issues at really cold temperatures with the ARB air lockers. Eaton didn’t offer an E-locker for Dana 70 axles at that time (maybe they do now- I honestly don’t know) so they used ARB air lockers on Tuckers with Dana 70 axles.

The original E-locker design for the Dana 60 axle was a two pinion design whereas the ARB unit for the Dana 60 was a four pinion design: advantage ARB. However, Eaton redesigned the E-locker and introduced a four pinion E-locker for the Dana 60 (along with a price increase…naturally). So strength-wise I think they’re about equal.

I also remember seeing a photo of a big Tucker groomer that was stuck just off a groomed trail. As I recall the story behind the photo, the operator was going about his business grooming the trail when a snowmobile traveling at a high rate of speed was blasting along the trail in the opposite direction. The snowcat operator intentionally drove off the trail to avoid a collision. But he was now stuck, and with a drag he couldn't back up. With open differentials, just like in a car/truck/whatever you can have one track spinning in front and one in back and go nowhere. With a locking differential both tracks will spin, and that may be enough added traction to get you out.

The selectable lockers give you the option of locking or not at your discretion; the best of both worlds. From my perspective, the only downside is the cost of the locker (and installation).

All that is true but with the power you are throwing at it, its just another reason to break an axle. I tend to modify things too, and learned from breaking thinks that all of the components have to match in strength. Letting the tracks slip may let it live, like an open diff. on the street you will just spin one tire, add positive traction with tires and that stock diff. will explode. Its almost a guarantee that if you were able to load it real hard and the tracks didn't slip, something will break. If you are seriously disciplined and only used the lockers to get un stuck it might live, but when stuck is when you are likely to load it real hard getting un stuck. You might be better off carrying extra rigging and an anchor to use a winch. The work you are doing on it looks very good.I’m not sure why….

I recall a conversation with the late Bill Guthrie who told me of a blade-equipped Tucker that was used at a sugar beet processing facility somewhere in Idaho. They used it to climb piles of sugar beets and to move them around. Bill said that with the locking differentials it was more or less unstoppable. In conversations with Jeff Godard at Tucker, Inc we discussed selectable lockers. He said Tucker has used both the ARB air lockers and the Eaton E-lockers. They preferred the E-lockers to the ARB units as they experienced some air line freezing issues at really cold temperatures with the ARB air lockers. Eaton didn’t offer an E-locker for Dana 70 axles at that time (maybe they do now- I honestly don’t know) so they used ARB air lockers on Tuckers with Dana 70 axles.

The original E-locker design for the Dana 60 axle was a two pinion design whereas the ARB unit for the Dana 60 was a four pinion design: advantage ARB. However, Eaton redesigned the E-locker and introduced a four pinion E-locker for the Dana 60 (along with a price increase…naturally). So strength-wise I think they’re about equal.

I also remember seeing a photo of a big Tucker groomer that was stuck just off a groomed trail. As I recall the story behind the photo, the operator was going about his business grooming the trail when a snowmobile traveling at a high rate of speed was blasting along the trail in the opposite direction. The snowcat operator intentionally drove off the trail to avoid a collision. But he was now stuck, and with a drag he couldn't back up. With open differentials, just like in a car/truck/whatever you can have one track spinning in front and one in back and go nowhere. With a locking differential both tracks will spin, and that may be enough added traction to get you out.

The selectable lockers give you the option of locking or not at your discretion; the best of both worlds. From my perspective, the only downside is the cost of the locker (and installation).

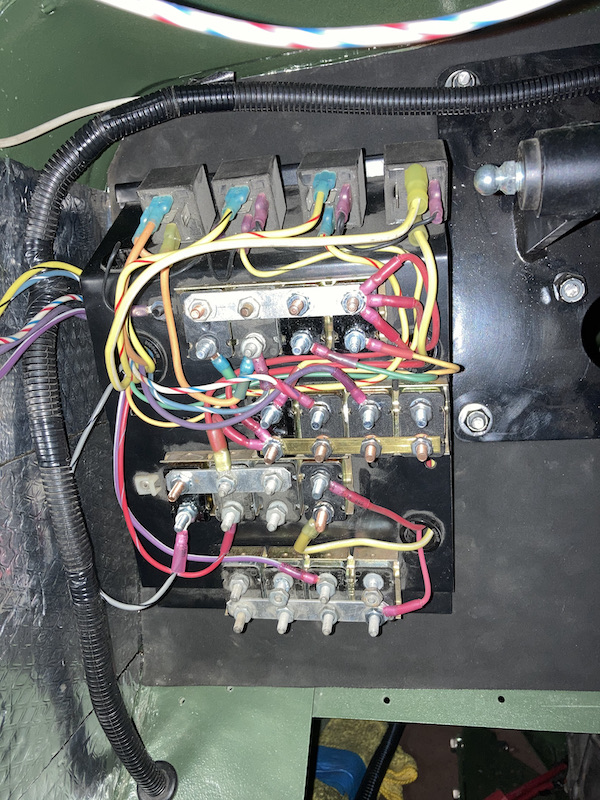

We’ve been making some progress on Putri-Zilla’s wiring....

The relay and circuit breaker panel is in position and we’ve been pulling wires to that location. But the instrument panel with the gauges and switches is also a big part of the equation. The horn, front LED light bar and the headlights in both the dim and bright modes all have relays, which means extra wires. But pulling wire, determining the correct length and then adding crimped on terminals is a surprisingly slow process.

Here's that panel mounted on the inside of the firewall on the left side. The firewall was first covered with sound deadening material and then covered with black neoprene foam. The foam might add some slight insulative and sound deadening capability but really we used it to cover the bright aluminum surface of the sound deadening material.

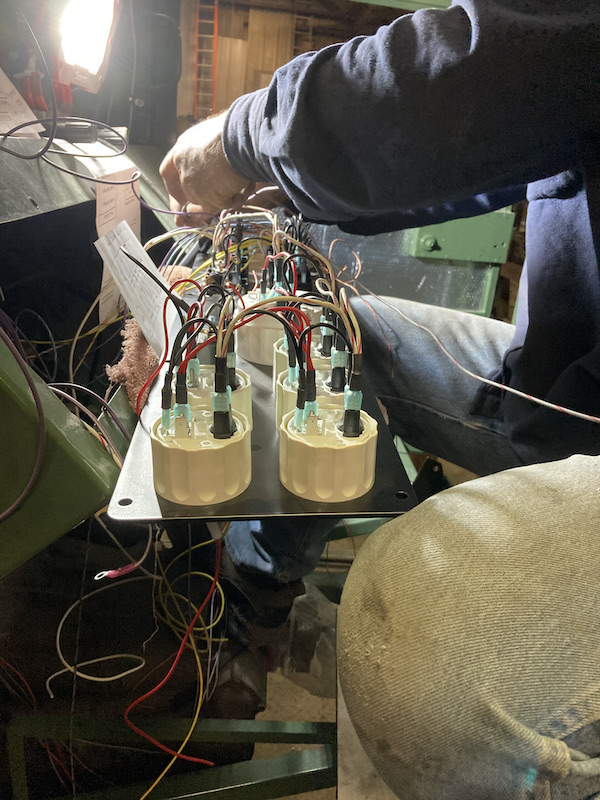

All of the wires connect to the gauges and switches on the back side of the instrument panel. If you install the panel first you then lay on your back, reach over your head, try and see what you're doing as you work. It’s not comfortable and it’s not fun. There’s got to be a better way so Scott bent some metal brackets that slide over the bottom of the steel dash panel opening, covered the brackets with a towel and laid the instrument panel upside down on the towel. Then he put a piece of melamine across some frame crossmembers and placed a short stool on the melamine. Once his “nest” was built, he climbed in and got to "work”.

I put work in quotes because someone was on the outside as the go-fer, grunt, or whatever term you want to use for the guy on the outside. That was me. We have a document that lists every circuit, and the color code and gauge for the wire used in that circuit. I’d look up what color wire went to a particular circuit, find it and hand it to him. Then he’d want a particular type of terminal, or wire cutters or crimpers or the heat gun. He had different sheets of paper that showed how the different switch configurations had to be wired, as well as an upside down diagram of the switch layout. Of course he’d “periodically" (more correctly frequently) drop stuff and guess who had to crawl under the machine to fetch the dropped items? Naturally there was a near constant litany of complaint that I wasn’t fast enough in getting him items to match his whim. I would tell him “No jury would convict me” as-in his impending homicide would be justifiable.

Here’s the instrument panel upside down and laid on the towel covered brackets.

You can see the melamine board and stool positioned Scott well to work on the wiring. MUCH better than laying on your back and working overhead.

A photo of the never satisfied slave driver.

But we did make some progress…thankfully. This week is crucial. If we are able to complete the wiring I think there’s a reasonably good chance Putri-Zilla will make it to SV 2022, and its big brother Thundercat will as well...

The relay and circuit breaker panel is in position and we’ve been pulling wires to that location. But the instrument panel with the gauges and switches is also a big part of the equation. The horn, front LED light bar and the headlights in both the dim and bright modes all have relays, which means extra wires. But pulling wire, determining the correct length and then adding crimped on terminals is a surprisingly slow process.

Here's that panel mounted on the inside of the firewall on the left side. The firewall was first covered with sound deadening material and then covered with black neoprene foam. The foam might add some slight insulative and sound deadening capability but really we used it to cover the bright aluminum surface of the sound deadening material.

All of the wires connect to the gauges and switches on the back side of the instrument panel. If you install the panel first you then lay on your back, reach over your head, try and see what you're doing as you work. It’s not comfortable and it’s not fun. There’s got to be a better way so Scott bent some metal brackets that slide over the bottom of the steel dash panel opening, covered the brackets with a towel and laid the instrument panel upside down on the towel. Then he put a piece of melamine across some frame crossmembers and placed a short stool on the melamine. Once his “nest” was built, he climbed in and got to "work”.

I put work in quotes because someone was on the outside as the go-fer, grunt, or whatever term you want to use for the guy on the outside. That was me. We have a document that lists every circuit, and the color code and gauge for the wire used in that circuit. I’d look up what color wire went to a particular circuit, find it and hand it to him. Then he’d want a particular type of terminal, or wire cutters or crimpers or the heat gun. He had different sheets of paper that showed how the different switch configurations had to be wired, as well as an upside down diagram of the switch layout. Of course he’d “periodically" (more correctly frequently) drop stuff and guess who had to crawl under the machine to fetch the dropped items? Naturally there was a near constant litany of complaint that I wasn’t fast enough in getting him items to match his whim. I would tell him “No jury would convict me” as-in his impending homicide would be justifiable.

Here’s the instrument panel upside down and laid on the towel covered brackets.

You can see the melamine board and stool positioned Scott well to work on the wiring. MUCH better than laying on your back and working overhead.

A photo of the never satisfied slave driver.

But we did make some progress…thankfully. This week is crucial. If we are able to complete the wiring I think there’s a reasonably good chance Putri-Zilla will make it to SV 2022, and its big brother Thundercat will as well...

I am not convinced SCOTT is the slave driver. I am thinking maybe the other way around......

Puh Leez....I am not convinced SCOTT is the slave driver. I am thinking maybe the other way around......

Did Scott put you up to suggesting that?

We continue to chip away at the wiring. We had some bad news regarding a mutual friend’s health and lost a night of work. And Scott had another commitment one night, so while I was hoping for a big week of progress, we fell short…again.

I shared with Scott my previous update and he protested that he was not a slave driver, but was (get this) “pure, white, and innocent”. Uh huh, and I have a bridge for sale in New York City. “Sweet” WBJ1, “pure, white, and innocent” Scott…I see a trend of wishful thinking.

We thought we were done with the gauge and switch panel but discovered some issues which we’ll resolve next time. And of course we need to get some more parts to complete certain aspects, but that’s par for the course with us. That won’t hold us up…we have plenty to do.

We had planned on installing the heater but discovered orange overspray courtesy of Tucker’s laziness in masking during initial production. (Why would you assemble a vehicle and then paint it? You can do a much better and more thorough job painting first and then assembling.) We thought that orange overspray would look awful, so it will get repainted. The defroster duct hoses also had lots of overspray on them, but they also had some tears in the material, so they get replaced.

Wiring isn’t very exciting and photos are pretty much ho-hum. But everyone likes pics so…

These are the brackets I mentioned in my last update for supporting the gauge and switch panel (or "instrument panel”, if you prefer) upside down. They grab the lower part of the dash panel where it’s cut out for the gauge and switch panel. These simple brackets make working on the wiring so much easier. (The orange cap on the right is on the fuel pressure regulator/filter combination frequently used in LS engine swaps.)

Speaking of the gauge and switch panel, here’s a photo taken awhile ago with some missing items. Scott and I (really Scott) designed the layout using his CAD system. We used the same dimensions and mounting hole locations (the eight holes around the perimeter) that we used on Thundercat and they fit perfectly when we installed it. But for Putri-Zilla we needed to change the design to accommodate the differences in the gauges, switches, etc. We emailed the the new CAD file to StreamWorks, a local water jet company, and they cut it to our specs. These guys do very nice work at reasonable prices, and it’s impressive how closely they can maintain tolerances. (You can probably tell where this is going…)

So... the other night Scott decides to position the gauge and switch panel in position to see what the almost-finished product looks like and... some of the top holes don’t line up with the mounting holes in the dash panel. They’re off enough that you can’t cheat just a little and install it. (Famous fighter-pilot quote: “If you’re not cheating, you’re not trying.”)

I think I’ve mentioned this before, but I’ll repeat it, because it’s so annoying. Eli Whitney is most famous for inventing the cotton gin, but perhaps his biggest contribution was the concept of mass production. In 1789 he received a contract from the US Government to supply 10,000 muskets. Whitney came up with a manufacturing process that used standardized parts which were interchangeable. Only 191 years later (when Putri-Zilla was made) Tucker, Inc still hadn’t figured that out that seemingly basic concept.

To cover up the latest example of Tucker’s buffoonery we’ll have to get creative. We could, I suppose, slot the holes in the new aluminum panel, but that's lame. I'd rather a better solution than a band-aid. Tucker may not care...but we do.

Here we have the headlights on in the dim position.

And in bright.

If you’re thinking “That amount of light seems pretty excessive for a vehicle with a top speed of 15 MPH”, we agree with you. Completely. I guess The Infamous WBJ1 wants to see where he’ll be in a few minutes. I wonder if the earth’s curvature will prevent that?

I shared with Scott my previous update and he protested that he was not a slave driver, but was (get this) “pure, white, and innocent”. Uh huh, and I have a bridge for sale in New York City. “Sweet” WBJ1, “pure, white, and innocent” Scott…I see a trend of wishful thinking.

We thought we were done with the gauge and switch panel but discovered some issues which we’ll resolve next time. And of course we need to get some more parts to complete certain aspects, but that’s par for the course with us. That won’t hold us up…we have plenty to do.

We had planned on installing the heater but discovered orange overspray courtesy of Tucker’s laziness in masking during initial production. (Why would you assemble a vehicle and then paint it? You can do a much better and more thorough job painting first and then assembling.) We thought that orange overspray would look awful, so it will get repainted. The defroster duct hoses also had lots of overspray on them, but they also had some tears in the material, so they get replaced.

Wiring isn’t very exciting and photos are pretty much ho-hum. But everyone likes pics so…

These are the brackets I mentioned in my last update for supporting the gauge and switch panel (or "instrument panel”, if you prefer) upside down. They grab the lower part of the dash panel where it’s cut out for the gauge and switch panel. These simple brackets make working on the wiring so much easier. (The orange cap on the right is on the fuel pressure regulator/filter combination frequently used in LS engine swaps.)

Speaking of the gauge and switch panel, here’s a photo taken awhile ago with some missing items. Scott and I (really Scott) designed the layout using his CAD system. We used the same dimensions and mounting hole locations (the eight holes around the perimeter) that we used on Thundercat and they fit perfectly when we installed it. But for Putri-Zilla we needed to change the design to accommodate the differences in the gauges, switches, etc. We emailed the the new CAD file to StreamWorks, a local water jet company, and they cut it to our specs. These guys do very nice work at reasonable prices, and it’s impressive how closely they can maintain tolerances. (You can probably tell where this is going…)

So... the other night Scott decides to position the gauge and switch panel in position to see what the almost-finished product looks like and... some of the top holes don’t line up with the mounting holes in the dash panel. They’re off enough that you can’t cheat just a little and install it. (Famous fighter-pilot quote: “If you’re not cheating, you’re not trying.”)

I think I’ve mentioned this before, but I’ll repeat it, because it’s so annoying. Eli Whitney is most famous for inventing the cotton gin, but perhaps his biggest contribution was the concept of mass production. In 1789 he received a contract from the US Government to supply 10,000 muskets. Whitney came up with a manufacturing process that used standardized parts which were interchangeable. Only 191 years later (when Putri-Zilla was made) Tucker, Inc still hadn’t figured that out that seemingly basic concept.

To cover up the latest example of Tucker’s buffoonery we’ll have to get creative. We could, I suppose, slot the holes in the new aluminum panel, but that's lame. I'd rather a better solution than a band-aid. Tucker may not care...but we do.

Here we have the headlights on in the dim position.

And in bright.

If you’re thinking “That amount of light seems pretty excessive for a vehicle with a top speed of 15 MPH”, we agree with you. Completely. I guess The Infamous WBJ1 wants to see where he’ll be in a few minutes. I wonder if the earth’s curvature will prevent that?

Snowy Rivers

Well-known member

You guys are doing a fantastic job on this machine.

The detail work is awesome.

The detail work is awesome.

1boringguy

Well-known member

... too much money, a girl too pretty, a car too fast, ....... a snocat with too many photons, ....... what's that mean? Ain't no such thingWe continue to chip away at the wiring. We had some bad news regarding a mutual friend’s health and lost a night of work. And Scott had another commitment one night, so while I was hoping for a big week of progress, we fell short…again.

I shared with Scott my previous update and he protested that he was not a slave driver, but was (get this) “pure, white, and innocent”. Uh huh, and I have a bridge for sale in New York City. “Sweet” WBJ1, “pure, white, and innocent” Scott…I see a trend of wishful thinking.

We thought we were done with the gauge and switch panel but discovered some issues which we’ll resolve next time. And of course we need to get some more parts to complete certain aspects, but that’s par for the course with us. That won’t hold us up…we have plenty to do.

We had planned on installing the heater but discovered orange overspray courtesy of Tucker’s laziness in masking during initial production. (Why would you assemble a vehicle and then paint it? You can do a much better and more thorough job painting first and then assembling.) We thought that orange overspray would look awful, so it will get repainted. The defroster duct hoses also had lots of overspray on them, but they also had some tears in the material, so they get replaced.

Wiring isn’t very exciting and photos are pretty much ho-hum. But everyone likes pics so…

These are the brackets I mentioned in my last update for supporting the gauge and switch panel (or "instrument panel”, if you prefer) upside down. They grab the lower part of the dash panel where it’s cut out for the gauge and switch panel. These simple brackets make working on the wiring so much easier. (The orange cap on the right is on the fuel pressure regulator/filter combination frequently used in LS engine swaps.)

View attachment 140975

Speaking of the gauge and switch panel, here’s a photo taken awhile ago with some missing items. Scott and I (really Scott) designed the layout using his CAD system. We used the same dimensions and mounting hole locations (the eight holes around the perimeter) that we used on Thundercat and they fit perfectly when we installed it. But for Putri-Zilla we needed to change the design to accommodate the differences in the gauges, switches, etc. We emailed the the new CAD file to StreamWorks, a local water jet company, and they cut it to our specs. These guys do very nice work at reasonable prices, and it’s impressive how closely they can maintain tolerances. (You can probably tell where this is going…)

So... the other night Scott decides to position the gauge and switch panel in position to see what the almost-finished product looks like and... some of the top holes don’t line up with the mounting holes in the dash panel. They’re off enough that you can’t cheat just a little and install it. (Famous fighter-pilot quote: “If you’re not cheating, you’re not trying.”)

I think I’ve mentioned this before, but I’ll repeat it, because it’s so annoying. Eli Whitney is most famous for inventing the cotton gin, but perhaps his biggest contribution was the concept of mass production. In 1789 he received a contract from the US Government to supply 10,000 muskets. Whitney came up with a manufacturing process that used standardized parts which were interchangeable. Only 191 years later (when Putri-Zilla was made) Tucker, Inc still hadn’t figured that out that seemingly basic concept.

To cover up the latest example of Tucker’s buffoonery we’ll have to get creative. We could, I suppose, slot the holes in the new aluminum panel, but that's lame. I'd rather a better solution than a band-aid. Tucker may not care...but we do.

View attachment 140976

Here we have the headlights on in the dim position.

View attachment 140977

And in bright.

View attachment 140978

If you’re thinking “That amount of light seems pretty excessive for a vehicle with a top speed of 15 MPH”, we agree with you. Completely. I guess The Infamous WBJ1 wants to see where he’ll be in a few minutes. I wonder if the earth’s curvature will prevent that?

I like the way you think!!!... too much money, a girl too pretty, a car too fast, ....... a snocat with too many photons, ....... what's that mean? Ain't no such thing

the lights are so blinding, wow, but with these lights will prevent anyone from seeing the awful baby shit green color, on, what should be a Orange Tucker snow cat

not a fan of lighting up the night sky so the space station can see you,

but

I this case, the LED lights are a great idea, more lights please, can't see the BSG paint, blinded by the lights !!!!!!!!!!!!!!!!!!!!!!!!

are you guys going to run an separate Honda generator for the lights ?

please leave the lights ON....

not a fan of lighting up the night sky so the space station can see you,

but

I this case, the LED lights are a great idea, more lights please, can't see the BSG paint, blinded by the lights !!!!!!!!!!!!!!!!!!!!!!!!

are you guys going to run an separate Honda generator for the lights ?

please leave the lights ON....

Last edited:

western auto

Active member

probably a dumb question........ whats the deal with that black piece of diamond plate on the side, i like the green but thats killing the look

probably a dumb question........ whats the deal with that black piece of diamond plate on the side, i like the green but thats killing the loo

I know

I know

I know

they are scuff plates, there are ladders that go on the side of the body, where the scuff plates are....

Exactly what PP said...I know

I know

I know

they are scuff plates, there are ladders that go on the side of the body, where the scuff plates are....

Here's a pic prior to removing the roof-top carrier and ladders for media blasting and powdercoating, and before the color change from BSG to Toyota "Army Green" (which looks like another shade of BSG to me).

And, oh look, yet another LED light bar mounted on the roof-top carrier!

While there is quite a bit of distance between the cab side and the ladder we thought it prudent to add the scuff plates to protect the cab sheet metal.

Snowy Rivers,

Thanks for the kind words. Very much appreciated, and especially so from someone so knowledgeable, talented and skilled.

1BG and PP,

While I agree with 1BG's first three examples, I question the last. We’ve all driven at night when oncoming traffic has super-bright lights that are almost blinding, and we’ve also had people behind us with similar lights. Very definitely tips the meter into the obnoxious part of the scale. Putri-Zilla is equipped with lights that have all of that capability... and more.

Now picture The Infamous WBJ1 behind the wheel. Yeah, he tries to come off as “sweet” or “kind" or “benevolent", but that’s all a ruse to hide his true persona. Picture a mad scientists with his finger on the button, and salivating at the possibilities. That’s what I’m envisioning….

The L94 really is a heck of an engine. It was used in GM luxury SUVs (Cadillac Escalade and GMC Yukon Denali) from 2014 - 2016 and GM didn’t cheap-out on the alternator. It’s rated at 160 amps, and should be plenty capable of powering all of the lighting we’re installing on Putri-Zilla. That said, we were asked to design the new gauge and switch panel to have empty holes for additional switches. As such, there are four snap-in cover plates that would allow for electrical system "growth". I suspect if the project upgrade and modification list wasn’t frozen we’d be asked to install some flashing, multi-colored under cat lighting and perhaps a sound system that would echo through the mountain tops. Think of the mad scientist I suggested, and the possibilities are almost endless. But that stuff will have to come from somewhere else.

Thanks for the kind words. Very much appreciated, and especially so from someone so knowledgeable, talented and skilled.

1BG and PP,

While I agree with 1BG's first three examples, I question the last. We’ve all driven at night when oncoming traffic has super-bright lights that are almost blinding, and we’ve also had people behind us with similar lights. Very definitely tips the meter into the obnoxious part of the scale. Putri-Zilla is equipped with lights that have all of that capability... and more.

Now picture The Infamous WBJ1 behind the wheel. Yeah, he tries to come off as “sweet” or “kind" or “benevolent", but that’s all a ruse to hide his true persona. Picture a mad scientists with his finger on the button, and salivating at the possibilities. That’s what I’m envisioning….

The L94 really is a heck of an engine. It was used in GM luxury SUVs (Cadillac Escalade and GMC Yukon Denali) from 2014 - 2016 and GM didn’t cheap-out on the alternator. It’s rated at 160 amps, and should be plenty capable of powering all of the lighting we’re installing on Putri-Zilla. That said, we were asked to design the new gauge and switch panel to have empty holes for additional switches. As such, there are four snap-in cover plates that would allow for electrical system "growth". I suspect if the project upgrade and modification list wasn’t frozen we’d be asked to install some flashing, multi-colored under cat lighting and perhaps a sound system that would echo through the mountain tops. Think of the mad scientist I suggested, and the possibilities are almost endless. But that stuff will have to come from somewhere else.

Still not done with the wiring. But first… Putri-Zilla has picked up another name: The Green Weenie….

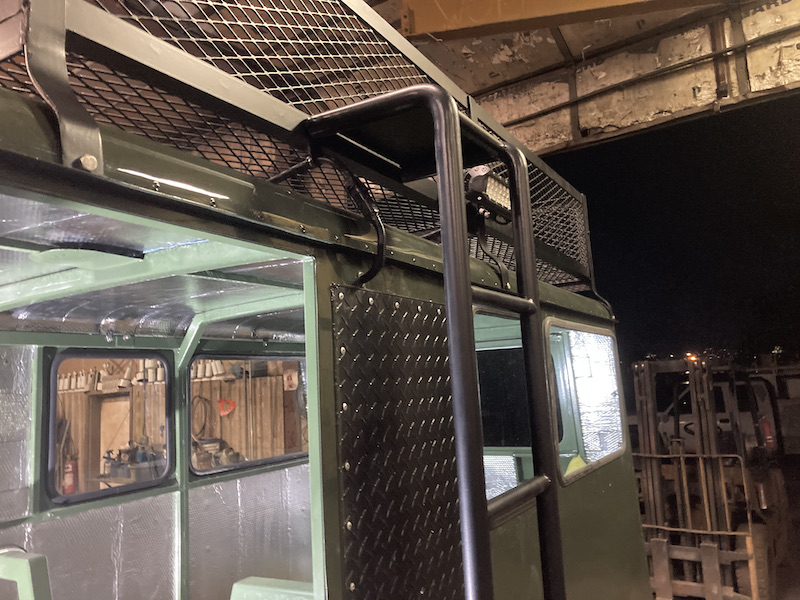

We sorted out the issues with the gauge and switch panel in short order and then focused our attention on other tasks. As I mentioned in a recent post, the roof-top carrier and ladders had been sent out for blasting and powder coating. It was time to install the rotating beacon (which uses what The Infamous WBJ1 calls “old school” bulbs (aka: incandescents)) the two side LED light bars, and the rear LED light bar. These are all bolted to the carrier and all the wires run underneath the carrier's frame. The wires run in split loom and the split loom is secured to the carrier with stainless steel cushion clamps and some of Scott’s beloved “zip screws”. I was concerned about the exposed sharp edges but he showed me if you whack the part of the screw that protrudes through the frame with a hammer, it will break off just about flush.

Here’s a pic of the underside of the roof-top carrier.

After completing the wiring we tested all the lights with a power supply and once light function was confirmed, we installed the carrier on Putri-Zilla. Besides power, all the lights needed to be properly grounded. We grounded the lights to the carrier and we installed external tooth washers between the carrier’s mounting brackets and Putri-Zilla’s roof skin. We also have a ground wire from the carrier to Putri-Zilla’s cab frame. We used a Weather Pack four-way plug between the carrier and the machine so if necessary, the plug can be disconnected, the carrier unbolted from Putri-Zilla and the carrier removed.

Incidentally, all split loom is not created equal. Basically the cheaper split loom, usually referred to as “poly” has a lower temperature rating. The better stuff has a higher temperature rating, is typically referred to as “nylon”, and has a light colored stripe running along the loom. (Split loom is also made in flame retardant and UV resistant varieties.) Yes, the better stuff is more expensive but if the poly loom is exposed to temperatures above its rating, it makes a mess that’s not fun to clean up. Yessum, that’s the voice of experience.

The ladders were bolted in place, and that part of the project is Finito! Stepping back and looking at the installed carrier both Scott and I think it looks good. Maybe part of the reason is when looking at it your eye’s attention is diverted from the green color?

Here’s a pic of the roof-top carrier and right side ladder installed. (Note the gloss on the green paint and how pure the reflection is!)

A pic of the left LED side light bar illuminated. Yes, it is bright!

The front LED light bar.

A shot of the left side ladder and how the wires come through the cab skin and connect to the carrier’s wiring via a Weather Pack plug. It's hard to see, but a rubber grommet seals and protects the split loom and wires where they penetrate the cab skin. It would have been a cleaner look had we run the wires through the roof skin, but minimizing roof penetrations is a good thing, and the roof’s drip edge offers some protection for the grommet.

A view of the inside The blue wires with white spiral tracers are for the dome lights.

At this point we have installed eight LED lights, but of course we aren’t done. In addition to the rear facing LED light bar on the roof top carrier (that’s probbaly 15-20 times brighter than the stock light Tucker installed) The Infamous WBJ1 wanted backup lights as well. True to form rather than select lights that were sufficient, he went for overkill. Both TUG (the DMC 1450) and the 1544 have a pair of LED backup lights. We used the same lights on both machines and each light is 18 watts. We think they’re great, and plenty bright…

But 18 watt lights on Putri-Zilla is too plebeian for good ol' WBJ1. Instead it will have two 54 watt LED light bars, the same lights that are mounted on the sides of the roof-top carrier. The backup lights are wired to turn on automatically when the transmission is shifted into reverse, and we also installed a manual switch for the lights on the gauge and switch panel. Unfortunately, that won’t complete the wiring, as Putri-Zilla also gets a backup camera.

We sorted out the issues with the gauge and switch panel in short order and then focused our attention on other tasks. As I mentioned in a recent post, the roof-top carrier and ladders had been sent out for blasting and powder coating. It was time to install the rotating beacon (which uses what The Infamous WBJ1 calls “old school” bulbs (aka: incandescents)) the two side LED light bars, and the rear LED light bar. These are all bolted to the carrier and all the wires run underneath the carrier's frame. The wires run in split loom and the split loom is secured to the carrier with stainless steel cushion clamps and some of Scott’s beloved “zip screws”. I was concerned about the exposed sharp edges but he showed me if you whack the part of the screw that protrudes through the frame with a hammer, it will break off just about flush.

Here’s a pic of the underside of the roof-top carrier.

After completing the wiring we tested all the lights with a power supply and once light function was confirmed, we installed the carrier on Putri-Zilla. Besides power, all the lights needed to be properly grounded. We grounded the lights to the carrier and we installed external tooth washers between the carrier’s mounting brackets and Putri-Zilla’s roof skin. We also have a ground wire from the carrier to Putri-Zilla’s cab frame. We used a Weather Pack four-way plug between the carrier and the machine so if necessary, the plug can be disconnected, the carrier unbolted from Putri-Zilla and the carrier removed.

Incidentally, all split loom is not created equal. Basically the cheaper split loom, usually referred to as “poly” has a lower temperature rating. The better stuff has a higher temperature rating, is typically referred to as “nylon”, and has a light colored stripe running along the loom. (Split loom is also made in flame retardant and UV resistant varieties.) Yes, the better stuff is more expensive but if the poly loom is exposed to temperatures above its rating, it makes a mess that’s not fun to clean up. Yessum, that’s the voice of experience.

The ladders were bolted in place, and that part of the project is Finito! Stepping back and looking at the installed carrier both Scott and I think it looks good. Maybe part of the reason is when looking at it your eye’s attention is diverted from the green color?

Here’s a pic of the roof-top carrier and right side ladder installed. (Note the gloss on the green paint and how pure the reflection is!)

A pic of the left LED side light bar illuminated. Yes, it is bright!

The front LED light bar.

A shot of the left side ladder and how the wires come through the cab skin and connect to the carrier’s wiring via a Weather Pack plug. It's hard to see, but a rubber grommet seals and protects the split loom and wires where they penetrate the cab skin. It would have been a cleaner look had we run the wires through the roof skin, but minimizing roof penetrations is a good thing, and the roof’s drip edge offers some protection for the grommet.

A view of the inside The blue wires with white spiral tracers are for the dome lights.

At this point we have installed eight LED lights, but of course we aren’t done. In addition to the rear facing LED light bar on the roof top carrier (that’s probbaly 15-20 times brighter than the stock light Tucker installed) The Infamous WBJ1 wanted backup lights as well. True to form rather than select lights that were sufficient, he went for overkill. Both TUG (the DMC 1450) and the 1544 have a pair of LED backup lights. We used the same lights on both machines and each light is 18 watts. We think they’re great, and plenty bright…

But 18 watt lights on Putri-Zilla is too plebeian for good ol' WBJ1. Instead it will have two 54 watt LED light bars, the same lights that are mounted on the sides of the roof-top carrier. The backup lights are wired to turn on automatically when the transmission is shifted into reverse, and we also installed a manual switch for the lights on the gauge and switch panel. Unfortunately, that won’t complete the wiring, as Putri-Zilla also gets a backup camera.

so what is the story of the Orange paint above rear the door, by chance is it Tucker "Orange"

I am impressed with the work, you and Scott have and will continue to do, to thee "Green Weenie"

very well done......

pretty dang sure, this is all way too good for the chicken king

I am impressed with the work, you and Scott have and will continue to do, to thee "Green Weenie"

very well done......

pretty dang sure, this is all way too good for the chicken king

Last edited:

The orange paint was added at the painter’s discretion and serves multiple purposes:so what is the story of the Orange paint above rear the door, by chance is it Tucker "Orange"

- It shows allegiance to Tucker’s “Omaha Orange” heritage.

- It allows people looking at the machine to see, as opposed to try and visualize, exactly what the correct original color was (and should be).

- It then aids people in imagining what Putri-Zilla would look like “if only” it had been painted Omaha Orange in its entirety.

For most of this project Scott and I have been respectful of WBJ1’s wants with regard to modifications, repairs, upgrades, etc. In some cases we put our foot down and say “No”. For example, the left front seat is torn and the rear upholstery is aged and has some small tears. Despite all the work to the snowcat, and all the new and cool stuff, WBJ1 wants the seats as they are. YGTBSM! They will be reupholstered.

For me, the orange panel is a poke in the ribs reminding me I was a bonehead in agreeing to the color change to BSG….

CT,BFT's next rebuild contract for a Tucker will have a clause: You can have it any color you want, so long as you want Omaha Orange.

You'd absolutely be right IF there was going to be another Tucker project. But other than possibly some fairly simple stuff to do on the 1544, Putri-Zilla will be our last project Tucker of significance.

Ya, right. And they all lived happily ever after.will be our last project Tucker of significance.

The End

1boringguy

Well-known member

As you've said, the work and camaraderie are it's own reward, but it might be you and Scott's turn to spend a little more time out there in the snow, putting one to it's intended use for a while.CT,

You'd absolutely be right IF there was going to be another Tucker project. But other than possibly some fairly simple stuff to do on the 1544, Putri-Zilla will be our last project Tucker of significance.

Hope to see you guys out there.

rumor has it,As you've said, the work and camaraderie are it's own reward, but it might be you and Scott's turn to spend a little more time out there in the snow, putting one to it's intended use for a while.

Hope to see you guys out there.

both, the green weenie and thundercat will be at SV2022

Next up? Thiokol? Bombardier?CT,

You'd absolutely be right IF there was going to be another Tucker project. But other than possibly some fairly simple stuff to do on the 1544, Putri-Zilla will be our last project Tucker of significance.

rumor has it, BFT has landed upon something special...Next up? Thiokol? Bombardier?

Sno-Drifter and CiderTom,

Honestly, the plan is no more big Tucker projects (or snowcat projects, if you prefer, to include other brands). I started with one machine, then got up to three - and wanted to get back to one. I achieved that goal…and then a 1643 showed up on ksl.com. I PM’ed a forum member about it, and they blew it off. I couldn’t pass it up, but I had no plans to turn it into a huge project. Then that darn WBJ1 wanted to buy it and talked me into a long list of upgrades and modifications. (He may claim to be a lowly chicken wing salesman, be he can sell ice to Eskimos!) That’s similar to how the 1544 and TUG were acquired… too good to pass up. However, I am working on improving my fiscal discipline to resist such purchases in the future. (PP is not a good influence!)

1BG,

You bring up a very valid point. The US military tracks the number of maintenance hours per flight hour for various aircraft and depending on the source, it’s typically around 20-25 for fighter aircraft after they’ve matured a bit. I WISH we spent only 25 hours working on the machines for every hour of use. I don’t want to know the real number, because the relationship is absolutely abysmal.

I can say unequivocally that both SV 2020 and SV 2021 were spectacular events for Scott and for me. We enjoyed ourselves so much it just about made all the hours of work worth it, and we’re greatly looking forward to SV 2022. We will be there for sure, and hopefully The Green Weenie and Thundercat will be there with us.

Honestly, the plan is no more big Tucker projects (or snowcat projects, if you prefer, to include other brands). I started with one machine, then got up to three - and wanted to get back to one. I achieved that goal…and then a 1643 showed up on ksl.com. I PM’ed a forum member about it, and they blew it off. I couldn’t pass it up, but I had no plans to turn it into a huge project. Then that darn WBJ1 wanted to buy it and talked me into a long list of upgrades and modifications. (He may claim to be a lowly chicken wing salesman, be he can sell ice to Eskimos!) That’s similar to how the 1544 and TUG were acquired… too good to pass up. However, I am working on improving my fiscal discipline to resist such purchases in the future. (PP is not a good influence!)

1BG,

You bring up a very valid point. The US military tracks the number of maintenance hours per flight hour for various aircraft and depending on the source, it’s typically around 20-25 for fighter aircraft after they’ve matured a bit. I WISH we spent only 25 hours working on the machines for every hour of use. I don’t want to know the real number, because the relationship is absolutely abysmal.

I can say unequivocally that both SV 2020 and SV 2021 were spectacular events for Scott and for me. We enjoyed ourselves so much it just about made all the hours of work worth it, and we’re greatly looking forward to SV 2022. We will be there for sure, and hopefully The Green Weenie and Thundercat will be there with us.