Think there is a pontoon exemption for the orange mandate.

-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Snowzilla": A Comprehensive Tucker 1643 Project...

- Thread starter Blackfoot Tucker

- Start date

Y'all are gonna make PP blow a fuse!!!!

you kids, can paint tuckers any color you want, go for it.....I will even supply the non tucker orange finger paints

I will be stepping down as the princess of pontoons, I have failed...

will be taking a new position of pontoon minion

I will be stepping down as the princess of pontoons, I have failed...

will be taking a new position of pontoon minion

Last edited:

Sno-Drifter,See, there is not even one snow catter that doesn't do green.

Let the record reflect my green snowcat involvement is under extreme duress....

I wholeheartedly approve! The Snowcat Gods would be at rest from witnessing the travesty of BSG on SnowZillafor clarification, the kitten was owned by the USFS and NOT responsible for what color they painted, fyi, under the damn ugly green is factory tucker Orange.

I did not paint the kitten GREEN...

it is a sin against the snow cat GODS to willfully paint a tucker GREEN, so help your soul, sweet one

Davenet, that photo, is one of the very best I have ever seen, fabulous photo, unmatched

BFT, I will be over with the trailer to pickup BSGzilla, I am going to paint it the correct color, ORANGE, next week...and end the misery of the minions

Just say the word and we'll start removing the roof-top carrier, the gas tank and the newly installed Weatherguard box on the side.

That's like divine intervention to snatch victory from the jaws of defeat!

Yep, just like the color discussions about Fire Engines. Next up: cage match fisti-cuffs. NO NO NO. There is room for all snow cats. yellow,red,orange,omaha-orange blue, camo. Certainly, certain brands are associated with certain colors. But, I have seen bright blue coming out of a building on pacific hwy in Medford Oregon. And I will admit that while even the USMC mountain training sno-cats are omaha-orange there is room even for green and greenish army colors usually associated with plastic toy soldiers.

Lets agree to disagree, and resume the polite discussions of such uncontroversial things as: turbo vs normal aspirated, Tennessee Whisky vs Bourbon, nitro vs CO2 beer, fuel injection vs carburetor.......

Lets agree to disagree, and resume the polite discussions of such uncontroversial things as: turbo vs normal aspirated, Tennessee Whisky vs Bourbon, nitro vs CO2 beer, fuel injection vs carburetor.......

With the wiring phase almost complete, we shifted to other tasks. I wanted to get the Weatherguard box installed, and that went off pretty smoothly. We had installed outriggers to support the box by cutting square holes through the cab skin and welding pieces of square tube on top of the Tucker's truss frame. We must have welded those at a slight angle, because the box leans in slightly. As you add weight to the box the lean corrects somewhat, but we're considering adding some shims under the box to make it level.

Side view. (If you’re wondering what’s hanging off the rear step area, that’s a nylon strap Scott uses to move Putri-Zilla. He picks up the back of the machine with a forklift to move it in and out of the shop.)

A view from the front.

For the floor in the rear foot well area Tucker uses plywood and the original piece was due for replacement. We purchased a new piece of plywood, took careful measurements, marked the plywood and cut it to size. Good ol’ Murphy showed up as after the plywood had been cut, we found it had de-laminated in the middle of the sheet. It looked fine on all the edges but the inside was damaged. We brought the cut sheet back and exchanged it for a new one. Neither of us have seen this happen before.

Once the replacement plywood was cut to size and the green paint had dried, Scott secured it to the frame with eight self-drilling flat head screws.

Now it was time to start installing the gray carpet “upholstery”, and we thought it made sense to start on the roof. The chosen carpet has a linear grain to it. We had decided to orient the grain vertically on the side walls, so it wouldn’t catch dirt, but the question for the roof was “Do we position the grain parallel with the machine or perpendicular to it"? I asked Scott his thoughts and without missing a beat he says “Diagonally”. Mr. Helpful…. I can just picture him 40 years ago in high school history class and the teacher asking “Where was the Declaration of Independence signed” and Scott volunteering “At the bottom of the page”. Yup, that’s Scott.

Several months ago I had the opportunity to visit a company that makes absolutely gorgeous interiors for small, general aviation aircraft, predominately Beechcraft. They are not inexpensive but the creativity and craftsmanship are really impressive and naturally they use top quality materials. The owner shared with me that they don’t use contact cement, but rather a similar but stronger adhering product that holds up better in extended sun exposure; Landau Top Adhesive. That’s what we’re using on Putri-Zilla. It’s made for spraying and the consistency is less viscous than regular contact cement. We don’t spray it, but rather brush it on, and the thinner consistency is much easier to work with. Once again, I was the cutter and Scott was the installer. We took measurements and I cut the various pieces to size, then they were put in place to confirm proper fit. At that point the adhesive was applied and Scott then put the cut pieces into final position. The roof sections were the hardest to work with. You simply don’t have enough hands to hold the carpet panels in proper position to check the fit, so it came down to “Well we measured carefully and the pieces were cut accordingly. Let’s put the glue on and go for it.” And that plan worked perfectly; undoubtedly due to the cutter’s skill!

If you’re thinking “What did those morons install off center between the middle cushion clamps”? That’s actually a stainless steel bolt that is the front mount for the roof-top carrier.

Honestly, we have been pleasantly surprised how quickly the process has been moving (so far, anyway) and I will also admit it looks better than I thought it would. There are a total of 28 pieces of carpet on the roof, sidewalls and kick panels, and we have installed 17 of them. I hope to finish the other 11 early next week and then we’ll start on the rear cab where the seat bottom cushions attach. We're going to use the same recycled rubber material we used on Thundercat’s floor It's on order and should arrive within a week or so. Installing it will be very time consuming as it either fits together tightly like a jigsaw puzzle, or it looks like Bubba and Billy Bob did it after drinking a case (or two) of beer.

It’s also time to bring all the seats to an upholstery shop to have them recovered. The Infamous WBJ1 would probably be content to sit on an upside down bucket or milk crate, but he gets outvoted. (Picture the scene from the movie My Cousin Vinny and Judge Chamberlain Haller saying “Overruled” in his inimitable southern accent to one of Vinny’s objections.)

Side view. (If you’re wondering what’s hanging off the rear step area, that’s a nylon strap Scott uses to move Putri-Zilla. He picks up the back of the machine with a forklift to move it in and out of the shop.)

A view from the front.

For the floor in the rear foot well area Tucker uses plywood and the original piece was due for replacement. We purchased a new piece of plywood, took careful measurements, marked the plywood and cut it to size. Good ol’ Murphy showed up as after the plywood had been cut, we found it had de-laminated in the middle of the sheet. It looked fine on all the edges but the inside was damaged. We brought the cut sheet back and exchanged it for a new one. Neither of us have seen this happen before.

Once the replacement plywood was cut to size and the green paint had dried, Scott secured it to the frame with eight self-drilling flat head screws.

Now it was time to start installing the gray carpet “upholstery”, and we thought it made sense to start on the roof. The chosen carpet has a linear grain to it. We had decided to orient the grain vertically on the side walls, so it wouldn’t catch dirt, but the question for the roof was “Do we position the grain parallel with the machine or perpendicular to it"? I asked Scott his thoughts and without missing a beat he says “Diagonally”. Mr. Helpful…. I can just picture him 40 years ago in high school history class and the teacher asking “Where was the Declaration of Independence signed” and Scott volunteering “At the bottom of the page”. Yup, that’s Scott.

Several months ago I had the opportunity to visit a company that makes absolutely gorgeous interiors for small, general aviation aircraft, predominately Beechcraft. They are not inexpensive but the creativity and craftsmanship are really impressive and naturally they use top quality materials. The owner shared with me that they don’t use contact cement, but rather a similar but stronger adhering product that holds up better in extended sun exposure; Landau Top Adhesive. That’s what we’re using on Putri-Zilla. It’s made for spraying and the consistency is less viscous than regular contact cement. We don’t spray it, but rather brush it on, and the thinner consistency is much easier to work with. Once again, I was the cutter and Scott was the installer. We took measurements and I cut the various pieces to size, then they were put in place to confirm proper fit. At that point the adhesive was applied and Scott then put the cut pieces into final position. The roof sections were the hardest to work with. You simply don’t have enough hands to hold the carpet panels in proper position to check the fit, so it came down to “Well we measured carefully and the pieces were cut accordingly. Let’s put the glue on and go for it.” And that plan worked perfectly; undoubtedly due to the cutter’s skill!

If you’re thinking “What did those morons install off center between the middle cushion clamps”? That’s actually a stainless steel bolt that is the front mount for the roof-top carrier.

Honestly, we have been pleasantly surprised how quickly the process has been moving (so far, anyway) and I will also admit it looks better than I thought it would. There are a total of 28 pieces of carpet on the roof, sidewalls and kick panels, and we have installed 17 of them. I hope to finish the other 11 early next week and then we’ll start on the rear cab where the seat bottom cushions attach. We're going to use the same recycled rubber material we used on Thundercat’s floor It's on order and should arrive within a week or so. Installing it will be very time consuming as it either fits together tightly like a jigsaw puzzle, or it looks like Bubba and Billy Bob did it after drinking a case (or two) of beer.

It’s also time to bring all the seats to an upholstery shop to have them recovered. The Infamous WBJ1 would probably be content to sit on an upside down bucket or milk crate, but he gets outvoted. (Picture the scene from the movie My Cousin Vinny and Judge Chamberlain Haller saying “Overruled” in his inimitable southern accent to one of Vinny’s objections.)

got to paint the very bright and shiny handle on the tool box, yikes

otherwise

it looks like you are doing the best you can, for a couple knuckleheads, bless you hearts,

orange seats?

otherwise

it looks like you are doing the best you can, for a couple knuckleheads, bless you hearts,

orange seats?

Last edited:

Bar looks to be just a little short for this average size tree.I know for a fact, sno drifter stands out in the forest hugging his trees, mmm might he be doing this to measure the diameter to determine how big the chain saw bar needs to be?

Attachments

I would say a bit longer bar is in order !!!!Bar looks to be just a little short for this average size tree.

Snowy Rivers

Well-known member

Back in the summer of 2015 we contracted a company to log our place here.

The trees had not been harvested since 1937....10 years prior to my parents purchasing the property.

I had not been into the lower area of the place in years, but I knew there were some fair sized trees in there.

Late one afternoon one of the Fellers came walking into the yard (Standard size saw on his shoulder) and asked if I was the owner..."YES I AM"

Conversation ensued about what he had discovered down below....

I smiled and said "Oh ...maybe some old stumps in the 12 to 14 foot at the butt range.

The young guy had never seen anything that big.

The springboard notches are still visible even after all these years.

This time around we had some trees that were a touch over 6 feet at the butt....Only one mill that can handle stuff that big.

They had to go down to a mill in Riddle (Oregon)

Yeah.....back in 37 those boys cut the trees with LOOOOOOOOOOOOOOOONG hand saws.....Like the ones ya see all painted with pretty scenes hanging over a fireplace mantle in lodges these days.....

I think there were 5-6 loads of the big stuff that went to Riddle.......

Don't take many of those to fill a truck.

A bygone era .......

Now they want 10 inch to 32 inch stuff (Twigs)

The trees had not been harvested since 1937....10 years prior to my parents purchasing the property.

I had not been into the lower area of the place in years, but I knew there were some fair sized trees in there.

Late one afternoon one of the Fellers came walking into the yard (Standard size saw on his shoulder) and asked if I was the owner..."YES I AM"

Conversation ensued about what he had discovered down below....

I smiled and said "Oh ...maybe some old stumps in the 12 to 14 foot at the butt range.

The young guy had never seen anything that big.

The springboard notches are still visible even after all these years.

This time around we had some trees that were a touch over 6 feet at the butt....Only one mill that can handle stuff that big.

They had to go down to a mill in Riddle (Oregon)

Yeah.....back in 37 those boys cut the trees with LOOOOOOOOOOOOOOOONG hand saws.....Like the ones ya see all painted with pretty scenes hanging over a fireplace mantle in lodges these days.....

I think there were 5-6 loads of the big stuff that went to Riddle.......

Don't take many of those to fill a truck.

A bygone era .......

Now they want 10 inch to 32 inch stuff (Twigs)

Last edited:

The Thanksgiving holiday shortened our workweek to a measly two days. Meanwhile, SV 2022 is now seven days closer. That relationship is not good when you have a whole lot of work to get done.

I mentioned in my last post that we had installed 17 of the 28 carpet pieces that go on the roof, side walls, kick panels and end walls. We installed ten of the remaining eleven and then set about working on the rear seat area and the foot well. We first installed sound deadening mat on the sides of the footwell, and then on the seam where the footwell sides meet the rear seat area horizontal floor we installed adhesive backed aluminum tape. Next, we covered the foot well’s floor with sound deadening material. To try and minimize waste, lots of smaller pieces of the sound deadening mat were utilized.

Full coverage of sound deadening material in the rear of the cab.

A close-up of the taped seam I described.

We discussed different options for rear upholstery coverage. Certainly we wanted the black rubber for the foot well’s floor and we considered both rubber and carpet options for the foot well sides. Choosing rubber would almost guarantee an ugly seem at the same top location we used the aluminum tape on, but we were facing the same issue if we did the top and sides in separate pieces of carpet. Overlapping the carpet would solve that, but due to the shape and geometric relationship it would be impossible to do one side with only one piece of carpet. However we thought most of the seam would be covered by the seat bottom cushion, and that was our best option.

This is the right side front piece all glued in position. The carpet followed the sharp corner surprisingly well, and... no seam on the top corner!

The rear pieces will be the challenging ones...

I mentioned in my last post that we had installed 17 of the 28 carpet pieces that go on the roof, side walls, kick panels and end walls. We installed ten of the remaining eleven and then set about working on the rear seat area and the foot well. We first installed sound deadening mat on the sides of the footwell, and then on the seam where the footwell sides meet the rear seat area horizontal floor we installed adhesive backed aluminum tape. Next, we covered the foot well’s floor with sound deadening material. To try and minimize waste, lots of smaller pieces of the sound deadening mat were utilized.

Full coverage of sound deadening material in the rear of the cab.

A close-up of the taped seam I described.

We discussed different options for rear upholstery coverage. Certainly we wanted the black rubber for the foot well’s floor and we considered both rubber and carpet options for the foot well sides. Choosing rubber would almost guarantee an ugly seem at the same top location we used the aluminum tape on, but we were facing the same issue if we did the top and sides in separate pieces of carpet. Overlapping the carpet would solve that, but due to the shape and geometric relationship it would be impossible to do one side with only one piece of carpet. However we thought most of the seam would be covered by the seat bottom cushion, and that was our best option.

This is the right side front piece all glued in position. The carpet followed the sharp corner surprisingly well, and... no seam on the top corner!

The rear pieces will be the challenging ones...

you knuckleheads better be getting your priorities straight and up your hours per week and git-r-dun...

despite your lack luster work effort, looking pretty good for a couple knuckleheads

despite your lack luster work effort, looking pretty good for a couple knuckleheads

The Loveable Curmudgeon and The Sweet Gorilla!!you knuckleheads better be getting your priorities straight and up your hours per week and git-r-dun...

despite your lack luster work effort, looking pretty good for a couple knuckleheads

PP,

I assure you I am doing everything I can to move this project along as quickly as I can. Scott is so busy with work, life and a new “love interest”, it’s difficult to get/keep him focused on Putri-Zilla. The term “herding cats” is fair, and that would make me… The Cat Wrangler!

I assure you I am doing everything I can to move this project along as quickly as I can. Scott is so busy with work, life and a new “love interest”, it’s difficult to get/keep him focused on Putri-Zilla. The term “herding cats” is fair, and that would make me… The Cat Wrangler!

Hee Haw, head them up, move them out, rawhide, cat wrangler...PP,

I assure you I am doing everything I can to move this project along as quickly as I can. Scott is so busy with work, life and a new “love interest”, it’s difficult to get/keep him focused on Putri-Zilla. The term “herding cats” is fair, and that would make me… The Cat Wrangler!

Last edited:

This week we got in almost five nights of work! Friday was a short night... as Scott got in trouble for working even a few hours. But we did get a fair bit done this week.

As I alluded to earlier, the rear pieces of carpet were a challenge. The top of the rear seat floor area is shaped like a trapezoid and the vertical side of the foot well extends perpendicularly from the diagonal side of the trapezoid. To make it just a bit more difficult, the foot well stops short of the end of the trapezoid. Lots of careful measuring, then drawing the shape out on paper with dimensions helps visualize what exactly needs to be cut. That’s followed by still more careful measuring using straight edges and a framing square, before cutting; all the while thinking “I hope I don’t screw this up”. And... the result was two pieces that fit almost perfectly with just a little trimming required. This was one of those project victories when you think “Maybe I do know what I’m doing”…

If you’re curious as to how Tucker did it, here are some pics. The rear seat bottom cushions extend from close to the sidewall over the edge and into the foot well area, almost completely covering what I’ve been referring to as the “rear seat floor area”.

The seat bottom cushions stop short of the rear end of the cab and Tucker installed some carpet at the back of the rear seat floor area. They dealt with the seam issue with some aluminum trim.

With the rear complete except for the floor of the foot well, we moved up to the front floor area. Neither Scott nor I are the least bit impressed with Tucker’s floor panel design, or execution. But as I mentioned earlier, time constraints preclude a proper solution which would be throwing the Tucker factory’s efforts on the scrap heap and starting over. Therefore, we limited the scope of our work to making minor improvements to Tucker’s panels.

Before installing the front floor we needed to run the lines to and from the transmission cooler, and incorporate a transmission temperature sender as well. While we would prefer to use custom hoses with crimped-on fittings, those are much more costly than the more typical rubber hoses with worm drive hose clamps, and we are trying to minimize expenses for WBJ1, so that’s what we went with. There wasn’t much room to work with and it took three separate trips to hydraulic shops to get the combination of fittings that would work. We believe the place to measure the transmission temperature is where the fluid leaves the transmission enroute to the cooler. That will be a higher temperature than measuring the cooled fluid, and since heat damages the transmission components, you want to know how hot the fluid is. The fittings that thread into the transmission are an O-Ring Boss style and the one that the temperature sender got plumbed into was a challenge. The transmission has a breather cap and we had to remove that pressed-in fitting, thread in our new O-Ring Boss 90º elbow, and then reinstall the breather fitting. (There is such a thing as an extended height elbow, but that wouldn’t fit underneath the transmission tunnel cover.)

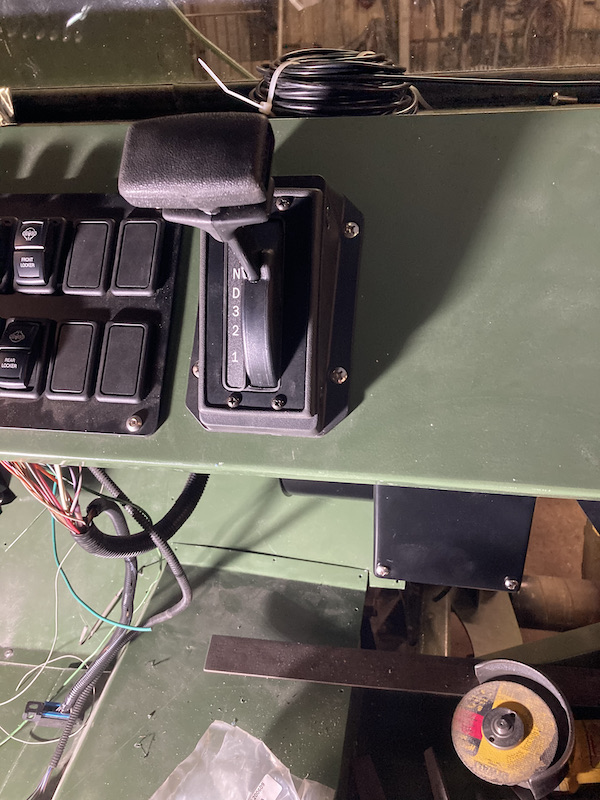

While making the multiple trips to get the right parts for the transmission cooler plumbing, we re-configured the transmission shifter and then installed that in the dash panel. More careful measuring to ensure it would fit properly over the heater’s fan motor, then cutting into the dash panel for the shifter mechanism installation. Our 1544 project came from the factory with an Allison AT 545 and we thought Tucker’s shifter setup with an optional mounting wedge worked well, so we used the same setup. Yes, some credit to Tucker!

Note how I refrained from making a remark about the ugly green color… (Oops, I guess I snuck that in.)

Another view.

Here’s pic of the Tucker factory floor panels where the transmission tunnel meets the right side front floor. I’ve owned three 1980 model Tuckers and all three have been the same. (Note: the brass fitting you see through the hole is for the transmission cooler supply line hose.)

Many companies who manufacture products make changes during production to improve product quality or to lower costs of manufacturing. Albert Einstein defined idiocy as doing the same thing over and over and expecting a different result. I think making the same mistake over and over, and being okay with a very obvious flaw is an even greater offense. Another Einstein quote “Two things are infinite, the universe and human stupidity; and I’m not sure about the universe”. I wonder what he’d say about Tucker?

We then installed sound deadening mat over the front floor. The piece that fits around the steering column is cut to shape but is not glued down as we’re waiting for a part that must be installed before the sound deadening mat can be glued down.

In theory, it should be possible to cover the mat with two pieces of rubber, but that’s a heck of a challenge as there is no cheating with the rubber, and the shape is very complex, which means lots of opportunities to make a mistake. Of course, in theory Tucker could have made the front floor in three pieces… and they didn’t even try. They used seven.

As I alluded to earlier, the rear pieces of carpet were a challenge. The top of the rear seat floor area is shaped like a trapezoid and the vertical side of the foot well extends perpendicularly from the diagonal side of the trapezoid. To make it just a bit more difficult, the foot well stops short of the end of the trapezoid. Lots of careful measuring, then drawing the shape out on paper with dimensions helps visualize what exactly needs to be cut. That’s followed by still more careful measuring using straight edges and a framing square, before cutting; all the while thinking “I hope I don’t screw this up”. And... the result was two pieces that fit almost perfectly with just a little trimming required. This was one of those project victories when you think “Maybe I do know what I’m doing”…

If you’re curious as to how Tucker did it, here are some pics. The rear seat bottom cushions extend from close to the sidewall over the edge and into the foot well area, almost completely covering what I’ve been referring to as the “rear seat floor area”.

The seat bottom cushions stop short of the rear end of the cab and Tucker installed some carpet at the back of the rear seat floor area. They dealt with the seam issue with some aluminum trim.

With the rear complete except for the floor of the foot well, we moved up to the front floor area. Neither Scott nor I are the least bit impressed with Tucker’s floor panel design, or execution. But as I mentioned earlier, time constraints preclude a proper solution which would be throwing the Tucker factory’s efforts on the scrap heap and starting over. Therefore, we limited the scope of our work to making minor improvements to Tucker’s panels.

Before installing the front floor we needed to run the lines to and from the transmission cooler, and incorporate a transmission temperature sender as well. While we would prefer to use custom hoses with crimped-on fittings, those are much more costly than the more typical rubber hoses with worm drive hose clamps, and we are trying to minimize expenses for WBJ1, so that’s what we went with. There wasn’t much room to work with and it took three separate trips to hydraulic shops to get the combination of fittings that would work. We believe the place to measure the transmission temperature is where the fluid leaves the transmission enroute to the cooler. That will be a higher temperature than measuring the cooled fluid, and since heat damages the transmission components, you want to know how hot the fluid is. The fittings that thread into the transmission are an O-Ring Boss style and the one that the temperature sender got plumbed into was a challenge. The transmission has a breather cap and we had to remove that pressed-in fitting, thread in our new O-Ring Boss 90º elbow, and then reinstall the breather fitting. (There is such a thing as an extended height elbow, but that wouldn’t fit underneath the transmission tunnel cover.)

While making the multiple trips to get the right parts for the transmission cooler plumbing, we re-configured the transmission shifter and then installed that in the dash panel. More careful measuring to ensure it would fit properly over the heater’s fan motor, then cutting into the dash panel for the shifter mechanism installation. Our 1544 project came from the factory with an Allison AT 545 and we thought Tucker’s shifter setup with an optional mounting wedge worked well, so we used the same setup. Yes, some credit to Tucker!

Note how I refrained from making a remark about the ugly green color… (Oops, I guess I snuck that in.)

Another view.

Here’s pic of the Tucker factory floor panels where the transmission tunnel meets the right side front floor. I’ve owned three 1980 model Tuckers and all three have been the same. (Note: the brass fitting you see through the hole is for the transmission cooler supply line hose.)

Many companies who manufacture products make changes during production to improve product quality or to lower costs of manufacturing. Albert Einstein defined idiocy as doing the same thing over and over and expecting a different result. I think making the same mistake over and over, and being okay with a very obvious flaw is an even greater offense. Another Einstein quote “Two things are infinite, the universe and human stupidity; and I’m not sure about the universe”. I wonder what he’d say about Tucker?

We then installed sound deadening mat over the front floor. The piece that fits around the steering column is cut to shape but is not glued down as we’re waiting for a part that must be installed before the sound deadening mat can be glued down.

In theory, it should be possible to cover the mat with two pieces of rubber, but that’s a heck of a challenge as there is no cheating with the rubber, and the shape is very complex, which means lots of opportunities to make a mistake. Of course, in theory Tucker could have made the front floor in three pieces… and they didn’t even try. They used seven.

That looks GREAT!! Should we change Scott's nickname from The Sweet Gorilla to The Lovestruck Gorilla??

"Sweet Gorilla” was/is as fantastical as "Sweet WBJ1”, or that Scott was “pure, white and innocent”. However, "Lovestruck Gorilla" seems very accurate based on current behavior.

I mentioned the new name last night (of course with proper attribution as to the source) and he protested only mildly. Then he announced he was told he “can’t” work on Friday nights anymore….

I mentioned the new name last night (of course with proper attribution as to the source) and he protested only mildly. Then he announced he was told he “can’t” work on Friday nights anymore….

So I was reading off these last few posts to Jenn and she asked a great question!! Will we get to meet The Lovestruck Gorilla's new lady at SV22???"Sweet Gorilla” was/is as fantastical as "Sweet WBJ1”, or that Scott was “pure, white and innocent”. However, "Lovestruck Gorilla" seems very accurate based on current behavior.

I mentioned the new name last night (of course with proper attribution as to the source) and he protested only mildly. Then he announced he was told he “can’t” work on Friday nights anymore….

There’s been a long delay since the last update. I wish I could say we were feverishly working and making lots of progress. Unfortunately, some medical issues on my part and some Lovestruck Gorilla lifestyle “constraints” put a serious crimp on our progress. And of course the ever-present typical project setbacks just made it that much worse.

We started the process of cutting and fitting the carpet section for under the front seats and glued that down, then started on the front floor rubber floor pieces. Scott and I talked about different options for how we’d divide up the floor, and how many individual pieces would make for the optimal installation. In my previous post I said it’s possible to do it in two pieces, but it would be challenging. We decided on three; not because two would be too difficult, but because where the panels would meet on the top front of the transmission tunnel would not look as good as if that piece was full length.

With Thundercat we made patterns for each piece and checked the fit before cutting rubber. It yields a great result, but it’s also hugely time consuming. We thought we would sacrifice a little of that precision for the sake of expediency and decided to omit the pattern making step of the process. Sure enough, the first piece I cut …was scrap. Scott had been working on the new battery mounting brackets and I decided to wait until he was done. Then we’d work together and simultaneously cross check the measuring and cutting methodology to create the correct cut shape. Much better results! But we had to wait for the steering column’s grommet to arrive to complete the floor installation process. In my experience some vendors deserve mention when they deliver consistently good service. When it comes to rubber grommets, my go-to supplier is Rubber Feet Warehouse in South Carolina. They have an excellent selection, great pricing, a reasonable minimum order size and shipping charges aren’t outrageous.

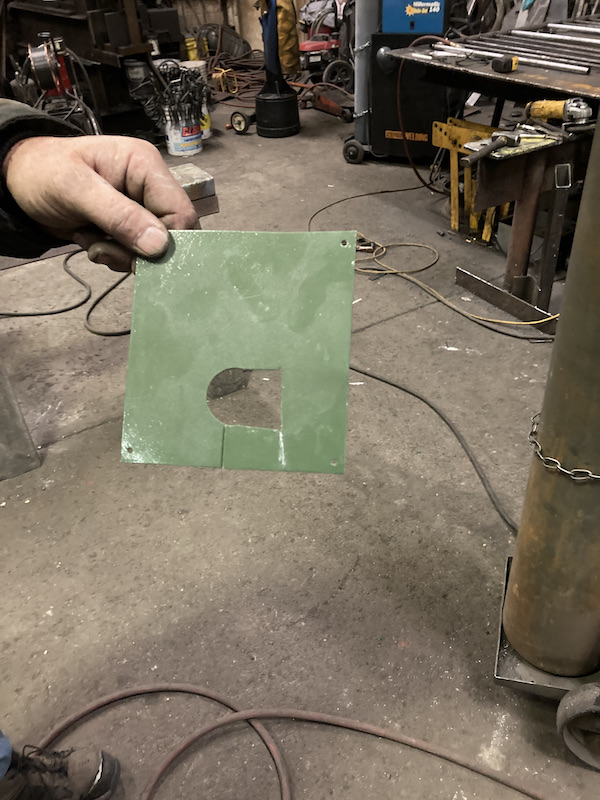

Backing up just a bit, here’s a pic of the panel Tucker uses around the steering column. In the photo the panel is backwards, the square side is actually on the left and it “fits” around the steering column’s horn wiring connection. In our opinion the steering wheel was too high, and we lowered it by moving the steering column down a few inches. That also meant the horn’s wiring connection was below the floor. We don’t care for the "cut loosely and gob some sealer around it” concept that describes the factory’s methods, so this panel was ripe for improvement.

Part of our earlier front floor panel design improvement resulted in cutting six inches from the panel that makes up the transmission tunnel. That provided a six inch wide length of BSG painted aluminum to work with! Scott squared one end in his “stomp shear” (a fairly light gauge metal shear that you actuate by forcefully pressing down on a large bar with your foot). Next he drilled a 1 3/4” hole in the panel with a hole saw. Then he carefully marked a line through the center of the hole from side-to-side and then he sheared the panel along the line. We’ll install a rubber grommet that meets our dimensional requirements to create a panel that seals well and looks good. Here’s the thing: this wasn’t time consuming, or difficult. It just took a little bit of thought and effort (heavy emphasis on little).

Side by side. Note the top of Tucker’s panel (on the left) isn’t even cut straight.

Here’s the installed panel with rubber grommet.

For comparison, this is factory. How well will flooring fit around the built up sealer? And how well will it adhere to it?

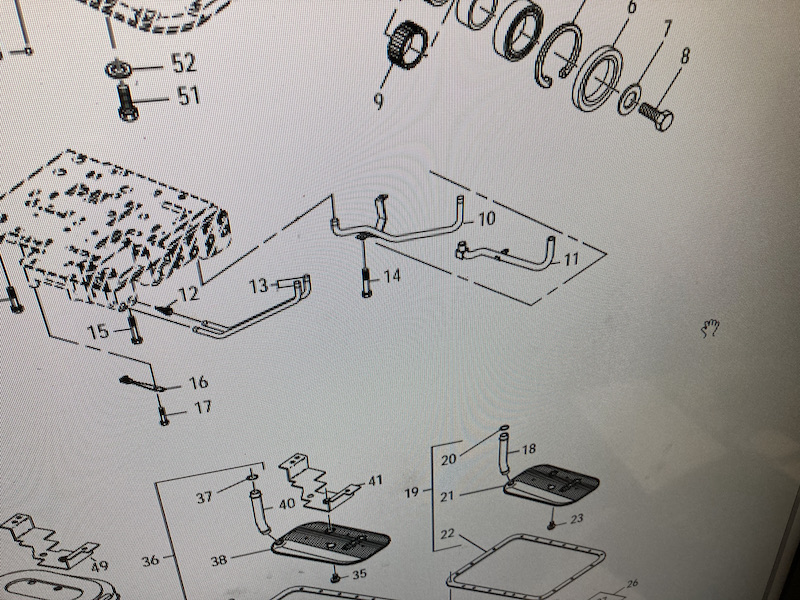

Also while waiting for the new grommet we spent some time on the transmission’s valve body. The Allison AT 545 was offered in either a single or double neutral shift pattern. This transmission had with a double neutral valve body and in the snowcat application we think the single neutral design is preferable. Some time ago I contacted a truck salvage yard and they told me they had a used single neutral valve body, and the price wasn’t bad, so I went to get it. But it turns out that transmission was installed behind a Diesel engine and there are some differences in the way the valve body is set up as compared to one installed with a gasoline engine. I was assured it wasn’t a big deal to make the changes, and that’s what we finally set about doing.

The valve body has several internal valves with springs as well as adjusting collars for tension. I was told we needed to swap the springs and adjust the collars to match. The springs are color coded so we carefully noted what came from where, and made the changes accordingly.

Here’s a pic showing some of the adjusting collars.

Then we ran into a wall. After reinstalling the valve body along with a new filter. Scott tried to bolt up a shallow transmission pan, also obtained from the salvage yard…but it wouldn’t fit. Huh? It turns out the shallow pan uses a different design short length of steel tube between the valve body and the transmission than is used on the deep pan. So we intrepidly made a trip to the local Allison dealer to get the short length of tube. Nope. Didn’t have it, and the parts guy thought it was unobtanium from Allison. He suggested we try Weller Transmission, which is a nationwide supplier of rebuilt Allison transmissions.

Before going any further, here’s a pic of an exploded view diagram. Part number 10 is the tube for the deep style transmission pan and part 11 is the design for the shallow pan.

If anything, it looks like the shallow design is simpler, and nothing looks particularly cosmic about it. I was thinking roughly $30, or so. Yeah… NO JOKE the price is just north of…wait for it… $320. Plus tax, plus shipping. HOLY CR*P! I don’t like the feeling of being taken advantage of, so note that there is no endorsement of Weller Transmission….

We’re pursuing other alternatives that are more cost effective…

Meanwhile, we’re back working on the floor. Here’s the left front floor with the sound deadening mat installed.

And with the rubber floor cut to fit, and glued down.

The center section of the floor was by far the most difficult as it required quite a bit of careful trimming to get the fit to an acceptable standard. The transmission tunnel sides were particularly challenging and we had to stick the rubber material down and then add weight on top of the rubber to secure it in position while the glue dried. We used pieces of steel scrap Scott had, as well as gallon sized plastic Ziploc bags filled with sand. As I’m writing this, the various weights are still in position, so I don't have any pics of the finished front floor.

The rear floor was frustrating as well. We carefully cut the rubber to shape and glued it down…except the rubber would unstick and “bubble up” in places. So we’d press it back into place and it would bubble up again. This got old... fast, so I grabbed some more pieces of steel scrap to place on top of the areas that were bubbling up. No sooner than I’d get one area fixed, another would pop up, and it basically became a game of whack-a-mole with the recalcitrant rubber floor material. Hopefully, I got 'em all.

We started the process of cutting and fitting the carpet section for under the front seats and glued that down, then started on the front floor rubber floor pieces. Scott and I talked about different options for how we’d divide up the floor, and how many individual pieces would make for the optimal installation. In my previous post I said it’s possible to do it in two pieces, but it would be challenging. We decided on three; not because two would be too difficult, but because where the panels would meet on the top front of the transmission tunnel would not look as good as if that piece was full length.

With Thundercat we made patterns for each piece and checked the fit before cutting rubber. It yields a great result, but it’s also hugely time consuming. We thought we would sacrifice a little of that precision for the sake of expediency and decided to omit the pattern making step of the process. Sure enough, the first piece I cut …was scrap. Scott had been working on the new battery mounting brackets and I decided to wait until he was done. Then we’d work together and simultaneously cross check the measuring and cutting methodology to create the correct cut shape. Much better results! But we had to wait for the steering column’s grommet to arrive to complete the floor installation process. In my experience some vendors deserve mention when they deliver consistently good service. When it comes to rubber grommets, my go-to supplier is Rubber Feet Warehouse in South Carolina. They have an excellent selection, great pricing, a reasonable minimum order size and shipping charges aren’t outrageous.

Backing up just a bit, here’s a pic of the panel Tucker uses around the steering column. In the photo the panel is backwards, the square side is actually on the left and it “fits” around the steering column’s horn wiring connection. In our opinion the steering wheel was too high, and we lowered it by moving the steering column down a few inches. That also meant the horn’s wiring connection was below the floor. We don’t care for the "cut loosely and gob some sealer around it” concept that describes the factory’s methods, so this panel was ripe for improvement.

Part of our earlier front floor panel design improvement resulted in cutting six inches from the panel that makes up the transmission tunnel. That provided a six inch wide length of BSG painted aluminum to work with! Scott squared one end in his “stomp shear” (a fairly light gauge metal shear that you actuate by forcefully pressing down on a large bar with your foot). Next he drilled a 1 3/4” hole in the panel with a hole saw. Then he carefully marked a line through the center of the hole from side-to-side and then he sheared the panel along the line. We’ll install a rubber grommet that meets our dimensional requirements to create a panel that seals well and looks good. Here’s the thing: this wasn’t time consuming, or difficult. It just took a little bit of thought and effort (heavy emphasis on little).

Side by side. Note the top of Tucker’s panel (on the left) isn’t even cut straight.

Here’s the installed panel with rubber grommet.

For comparison, this is factory. How well will flooring fit around the built up sealer? And how well will it adhere to it?

Also while waiting for the new grommet we spent some time on the transmission’s valve body. The Allison AT 545 was offered in either a single or double neutral shift pattern. This transmission had with a double neutral valve body and in the snowcat application we think the single neutral design is preferable. Some time ago I contacted a truck salvage yard and they told me they had a used single neutral valve body, and the price wasn’t bad, so I went to get it. But it turns out that transmission was installed behind a Diesel engine and there are some differences in the way the valve body is set up as compared to one installed with a gasoline engine. I was assured it wasn’t a big deal to make the changes, and that’s what we finally set about doing.

The valve body has several internal valves with springs as well as adjusting collars for tension. I was told we needed to swap the springs and adjust the collars to match. The springs are color coded so we carefully noted what came from where, and made the changes accordingly.

Here’s a pic showing some of the adjusting collars.

Then we ran into a wall. After reinstalling the valve body along with a new filter. Scott tried to bolt up a shallow transmission pan, also obtained from the salvage yard…but it wouldn’t fit. Huh? It turns out the shallow pan uses a different design short length of steel tube between the valve body and the transmission than is used on the deep pan. So we intrepidly made a trip to the local Allison dealer to get the short length of tube. Nope. Didn’t have it, and the parts guy thought it was unobtanium from Allison. He suggested we try Weller Transmission, which is a nationwide supplier of rebuilt Allison transmissions.

Before going any further, here’s a pic of an exploded view diagram. Part number 10 is the tube for the deep style transmission pan and part 11 is the design for the shallow pan.

If anything, it looks like the shallow design is simpler, and nothing looks particularly cosmic about it. I was thinking roughly $30, or so. Yeah… NO JOKE the price is just north of…wait for it… $320. Plus tax, plus shipping. HOLY CR*P! I don’t like the feeling of being taken advantage of, so note that there is no endorsement of Weller Transmission….

We’re pursuing other alternatives that are more cost effective…

Meanwhile, we’re back working on the floor. Here’s the left front floor with the sound deadening mat installed.

And with the rubber floor cut to fit, and glued down.

The center section of the floor was by far the most difficult as it required quite a bit of careful trimming to get the fit to an acceptable standard. The transmission tunnel sides were particularly challenging and we had to stick the rubber material down and then add weight on top of the rubber to secure it in position while the glue dried. We used pieces of steel scrap Scott had, as well as gallon sized plastic Ziploc bags filled with sand. As I’m writing this, the various weights are still in position, so I don't have any pics of the finished front floor.

The rear floor was frustrating as well. We carefully cut the rubber to shape and glued it down…except the rubber would unstick and “bubble up” in places. So we’d press it back into place and it would bubble up again. This got old... fast, so I grabbed some more pieces of steel scrap to place on top of the areas that were bubbling up. No sooner than I’d get one area fixed, another would pop up, and it basically became a game of whack-a-mole with the recalcitrant rubber floor material. Hopefully, I got 'em all.

The darn moles beat me. I thought I had everything covered, but when I turned my back a couple new bubbles showed up that I didn’t see. ARRRGGGH! Not horrific, but not the way it should be.

A long time ago we had cut off the factory battery mounting bracket and a scabbed-on rather pathetic winch battery bracket a previous owned added. The plan had been to design and fabricate new ones later on. The downside of this is we knew we’d damage the paint and have to do some touch-up, but that’s the route we took and now it’s time to address locating and installing the batteries. Putri-Zilla came with the optional front Warn winch and as an electric winch it runs off the vehicle’s electrical system. It’s possible when using an electric winch to deplete the vehicle battery to the point if the engine stalls, the battery doesn’t have enough juice left to re-start the engine. To prevent this, many people will install a second battery AND also install a battery separator. That allows one battery for the engine and the other for the winch, but both are tied into the alternator for charging purposes through the battery separator.

Again, we tossed ideas back and forth and one of the objectives was to keep the batteries away from the engine’s heat. We decided to put the vehicle battery on the left side, close to the firewall (slightly aft of where Tucker installed it) and the winch’s battery on the right side just behind the radiator. The factory battery mounting brackets are made from 3/4” angle and they have support legs also made of 3/4” angle welded to the frame. Our 1544 also came with a factory installed winch and it had two batteries. The vehicle battery was mounted with the usual 3/4” angle legs and where they were welded to the frame had broken, been re welded and broken at least twice more. It was a mess! Scott explained to me a long time ago that square tube is strongest in the corners and weakest in the middle. I bet you know where those legs were welded!

If you think about the surface area of a 3/4” angle that’s only 1/8” thick, you realize all that battery weight is concentrated in a small area, and that concentrated stress makes failure more likely. We chose to make our brackets from 1” angle (that’s what Scott had on hand) and the support legs from 1 1/2” x 1” rectangular tube with a 1/8” wall thickness. That spreads the weight better, but the engine side vertical wall of the frame’s square tubing was being occupied by wires on the left side, and transmission cooler lines on the right side. That meant our diagonal support legs would be welded to the uprights, and that concentrated more weight on them. To add strength to the frame’s square tube Scott suggested cutting some elongated holes into the frame square tube to weld internal support members, then weld up the holes and clean up the welds to hide everything. The battery bracket support legs are welded directly on top of the supports. The concept is that the weight of the battery on the bracket wants to lift the center of the frame tube where it’s weakest. If we added internal support members welded to the top where the support members will be welded, and also on a bottom corner of the frame tube it will add considerable strength the to mounting design and it’s all hidden. Credit for this design and the fabrication goes to the Lovestruck Gorilla. On a fairly frequent basis he comes up with some creative and effective ideas. I do try and give him the credit he deserves and that’s why I say “He’s the brains and talent…and I’m the one with the bonehead ideas”.

Here’s a pic with the right side reinforcement plates in position before welding. The attached rods are for positioning the support plates until they are tack welded in position.

Here’s one of the lower cuts where the reinforcement plates get welded toward the bottom of the square tube on the inside.

We built the battery brackets and I took them home and media blasted them. Painting them in place after welding them to the frame would have been difficult and I wanted a decent paint job. So we painted them off the machine knowing we’d subsequently have to touch up the paint after welding.

This pic is a little unfair. Scott does not like having his picture taken, and here he is doing final paint touch up with an airbrush. I had done most of the airbrush work and he threatened to take my photo while I was doing so, but he kindly didn’t. Then I suggested he look over my work and I snapped this. He was not pleased. However, if you think of this as small retribution for the harassment I get... you’ll understand.

The finished product. (I still hate the color…)

A long time ago we had cut off the factory battery mounting bracket and a scabbed-on rather pathetic winch battery bracket a previous owned added. The plan had been to design and fabricate new ones later on. The downside of this is we knew we’d damage the paint and have to do some touch-up, but that’s the route we took and now it’s time to address locating and installing the batteries. Putri-Zilla came with the optional front Warn winch and as an electric winch it runs off the vehicle’s electrical system. It’s possible when using an electric winch to deplete the vehicle battery to the point if the engine stalls, the battery doesn’t have enough juice left to re-start the engine. To prevent this, many people will install a second battery AND also install a battery separator. That allows one battery for the engine and the other for the winch, but both are tied into the alternator for charging purposes through the battery separator.

Again, we tossed ideas back and forth and one of the objectives was to keep the batteries away from the engine’s heat. We decided to put the vehicle battery on the left side, close to the firewall (slightly aft of where Tucker installed it) and the winch’s battery on the right side just behind the radiator. The factory battery mounting brackets are made from 3/4” angle and they have support legs also made of 3/4” angle welded to the frame. Our 1544 also came with a factory installed winch and it had two batteries. The vehicle battery was mounted with the usual 3/4” angle legs and where they were welded to the frame had broken, been re welded and broken at least twice more. It was a mess! Scott explained to me a long time ago that square tube is strongest in the corners and weakest in the middle. I bet you know where those legs were welded!

If you think about the surface area of a 3/4” angle that’s only 1/8” thick, you realize all that battery weight is concentrated in a small area, and that concentrated stress makes failure more likely. We chose to make our brackets from 1” angle (that’s what Scott had on hand) and the support legs from 1 1/2” x 1” rectangular tube with a 1/8” wall thickness. That spreads the weight better, but the engine side vertical wall of the frame’s square tubing was being occupied by wires on the left side, and transmission cooler lines on the right side. That meant our diagonal support legs would be welded to the uprights, and that concentrated more weight on them. To add strength to the frame’s square tube Scott suggested cutting some elongated holes into the frame square tube to weld internal support members, then weld up the holes and clean up the welds to hide everything. The battery bracket support legs are welded directly on top of the supports. The concept is that the weight of the battery on the bracket wants to lift the center of the frame tube where it’s weakest. If we added internal support members welded to the top where the support members will be welded, and also on a bottom corner of the frame tube it will add considerable strength the to mounting design and it’s all hidden. Credit for this design and the fabrication goes to the Lovestruck Gorilla. On a fairly frequent basis he comes up with some creative and effective ideas. I do try and give him the credit he deserves and that’s why I say “He’s the brains and talent…and I’m the one with the bonehead ideas”.

Here’s a pic with the right side reinforcement plates in position before welding. The attached rods are for positioning the support plates until they are tack welded in position.

Here’s one of the lower cuts where the reinforcement plates get welded toward the bottom of the square tube on the inside.

We built the battery brackets and I took them home and media blasted them. Painting them in place after welding them to the frame would have been difficult and I wanted a decent paint job. So we painted them off the machine knowing we’d subsequently have to touch up the paint after welding.

This pic is a little unfair. Scott does not like having his picture taken, and here he is doing final paint touch up with an airbrush. I had done most of the airbrush work and he threatened to take my photo while I was doing so, but he kindly didn’t. Then I suggested he look over my work and I snapped this. He was not pleased. However, if you think of this as small retribution for the harassment I get... you’ll understand.

The finished product. (I still hate the color…)

HankScorpio

Member

My 1544 has a battery tray just like yours here. It has been welded several times in its life. I had always figured it wasn't factory, but I guess it's in the stock Tucker location after all. If mine comes loose again I will probably steal your idea, nice work.The darn moles beat me. I thought I had everything covered, but when I turned my back a couple new bubbles showed up that I didn’t see. ARRRGGGH! Not horrific, but not the way it should be.

A long time ago we had cut off the factory battery mounting bracket and a scabbed-on rather pathetic winch battery bracket a previous owned added. The plan had been to design and fabricate new ones later on. The downside of this is we knew we’d damage the paint and have to do some touch-up, but that’s the route we took and now it’s time to address locating and installing the batteries. Putri-Zilla came with the optional front Warn winch and as an electric winch it runs off the vehicle’s electrical system. It’s possible when using an electric winch to deplete the vehicle battery to the point if the engine stalls, the battery doesn’t have enough juice left to re-start the engine. To prevent this, many people will install a second battery AND also install a battery separator. That allows one battery for the engine and the other for the winch, but both are tied into the alternator for charging purposes through the battery separator.

Again, we tossed ideas back and forth and one of the objectives was to keep the batteries away from the engine’s heat. We decided to put the vehicle battery on the left side, close to the firewall (slightly aft of where Tucker installed it) and the winch’s battery on the right side just behind the radiator. The factory battery mounting brackets are made from 3/4” angle and they have support legs also made of 3/4” angle welded to the frame. Our 1544 also came with a factory installed winch and it had two batteries. The vehicle battery was mounted with the usual 3/4” angle legs and where they were welded to the frame had broken, been re welded and broken at least twice more. It was a mess! Scott explained to me a long time ago that square tube is strongest in the corners and weakest in the middle. I bet you know where those legs were welded!

If you think about the surface area of a 3/4” angle that’s only 1/8” thick, you realize all that battery weight is concentrated in a small area, and that concentrated stress makes failure more likely. We chose to make our brackets from 1” angle (that’s what Scott had on hand) and the support legs from 1 1/2” x 1” rectangular tube with a 1/8” wall thickness. That spreads the weight better, but the engine side vertical wall of the frame’s square tubing was being occupied by wires on the left side, and transmission cooler lines on the right side. That meant our diagonal support legs would be welded to the uprights, and that concentrated more weight on them. To add strength to the frame’s square tube Scott suggested cutting some elongated holes into the frame square tube to weld internal support members, then weld up the holes and clean up the welds to hide everything. The battery bracket support legs are welded directly on top of the supports. The concept is that the weight of the battery on the bracket wants to lift the center of the frame tube where it’s weakest. If we added internal support members welded to the top where the support members will be welded, and also on a bottom corner of the frame tube it will add considerable strength the to mounting design and it’s all hidden. Credit for this design and the fabrication goes to the Lovestruck Gorilla. On a fairly frequent basis he comes up with some creative and effective ideas. I do try and give him the credit he deserves and that’s why I say “He’s the brains and talent…and I’m the one with the bonehead ideas”.

Here’s a pic with the right side reinforcement plates in position before welding. The attached rods are for positioning the support plates until they are tack welded in position.

View attachment 143908

Here’s one of the lower cuts where the reinforcement plates get welded toward the bottom of the square tube on the inside.

View attachment 143909

We built the battery brackets and I took them home and media blasted them. Painting them in place after welding them to the frame would have been difficult and I wanted a decent paint job. So we painted them off the machine knowing we’d subsequently have to touch up the paint after welding.

This pic is a little unfair. Scott does not like having his picture taken, and here he is doing final paint touch up with an airbrush. I had done most of the airbrush work and he threatened to take my photo while I was doing so, but he kindly didn’t. Then I suggested he look over my work and I snapped this. He was not pleased. However, if you think of this as small retribution for the harassment I get... you’ll understand.

View attachment 143910

The finished product. (I still hate the color…)

View attachment 143911

Now that SV 2022 is in the books (Phenomenal event!) Scott and I are back to other snowcat projects, and that means Putri-Zilla. I will mention that it almost was repainted its rightful orange, which would return the machine to its former glory as Snow-Zilla, but in the end the amount of work to do that seemed like a bridge too far. Putri-Zilla it shall ignominiously remain...

For those that weren’t at SV 2022, we brought Thundercat, and we did so without testing it in Utah first. It ran pretty well, though there are some issues to address. One of them is the transmission, and since the one installed in Putri-Zilla is close to identical, I thought I’d discuss it in this thread.

It’s been a while, so to refresh reader’s memories the transmission is an Allison AT545 (which is also installed in the 1544). Allison has a my transmission website that allows you to enter your transmission's serial number (located on a plate riveted to the right rear of the transmission) and you can see how your transmission was originally built at the factory. Whereas GM, for example, installed the Turbo 400 in numerous GM vehicles, bell housing bolt pattern differences between vehicle brands means you can’t put a transmission from an Oldsmobile behind a Chevrolet engine. The AT545 on the other hand is built with an SAE #3 bolt pattern on the transmission and uses an adapter housing on the engine side. That means you could take an AT545 originally installed in a bread van behind a Cummins 4BT engine, and using a different adapter housing, bolt it up to virtually any engine you can find an adapter housing for.

That’s pretty darn cool, but it also means the transmission’s configuration was optimized for the 4BT application and that setup is very likely less than optimal when the transmission is installed behind a different engine. Snow-Zilla's, (oops, I mean Putri-Zilla”s) transmission was originally installed in a school bus behind a Chevrolet big block engine. (Thundercat’s was installed in a Schwan’s Ice Cream truck).

For different applications Allison offers different transmission modulators and governors, as well as different valve body components and settings. Upon returning from SV 2022 I sought out the advice of the local Allison dealer/distributor/service center, Smith Power Products. Scott and I have been there multiple times and when we walk in…the parts guy covers his head. We are that well liked! Seriously though, they have been very helpful and the parts guy suggested I talk with the AT545 guru who has been at Smith for many years.

"Way back when" I spoke with Tucker, and after talking with the fellow Tucker worked with at the Allison dealer/distributor/service center near them, I purchased a modulator “plug” from Tucker. It’s a fixed, but adjustable mechanical modulator. In a conversation with Smith's night shop foreman he was decidedly against the modulator plug concept. He explained the AT545 was similar to some larger Allison transmissions, and in those transmissions when the modulators failed it almost always wiped out either first or fourth gear. So a few of their customers would install a fixed modulator plug in lieu of the normal modulator and that “solved" the problem. However, that also resulted in very harsh shifts. (We can confirm Thundercat's transmission shifts harshly.) The AT545 guru I mentioned recommended we start by replacing the modulator plug with an Allison “soft shift” vacuum modulator (Allison part number 29501199).

I’ve got one coming and we’re supposed to install that and report back on how it works. The next step may be to change the transmission’s governor. Allison makes three different governors for the AT545. One is for gasoline engines and the other two are for Diesels. (The difference in the Diesel governors being the engine's maximum RPM.) I took the three transmission serial numbers and looked them up on Allison’s my transmission website. Interestingly, the governor in the 1544’s transmission is the gasoline engine governor, but both of the other transmissions have the higher RPM Diesel engine governor.

Valve body adjustments may also be required. There are adjusting collars installed in front of the springs, and repositioning the adjusting collar will increase or decrease the RPMs at which the transmission shifts. (IIRC each notch in the adjusting collar makes roughly a 50-60 RPM difference in the shift point.) But if that isn’t enough, new springs may be required. There are also trimmer valves which might require some tweaking. The night shop foreman I mentioned said “... if one spends the time to fine tune the transmission, it can be adjusted to shift as smoothly as a car”. I’m a bit skeptical of that, but I believe we can significantly improve the shifting characteristics for our applications.

I know Tucker installed AT545s behind several different engines and in different snowcat models. As the time involved to get the configuration and adjustments right can be significant, I suspect they didn’t spend a whole lot of time refining the setup for any of them. That would also suggest there's room for improvement on our part.

For those that weren’t at SV 2022, we brought Thundercat, and we did so without testing it in Utah first. It ran pretty well, though there are some issues to address. One of them is the transmission, and since the one installed in Putri-Zilla is close to identical, I thought I’d discuss it in this thread.

It’s been a while, so to refresh reader’s memories the transmission is an Allison AT545 (which is also installed in the 1544). Allison has a my transmission website that allows you to enter your transmission's serial number (located on a plate riveted to the right rear of the transmission) and you can see how your transmission was originally built at the factory. Whereas GM, for example, installed the Turbo 400 in numerous GM vehicles, bell housing bolt pattern differences between vehicle brands means you can’t put a transmission from an Oldsmobile behind a Chevrolet engine. The AT545 on the other hand is built with an SAE #3 bolt pattern on the transmission and uses an adapter housing on the engine side. That means you could take an AT545 originally installed in a bread van behind a Cummins 4BT engine, and using a different adapter housing, bolt it up to virtually any engine you can find an adapter housing for.

That’s pretty darn cool, but it also means the transmission’s configuration was optimized for the 4BT application and that setup is very likely less than optimal when the transmission is installed behind a different engine. Snow-Zilla's, (oops, I mean Putri-Zilla”s) transmission was originally installed in a school bus behind a Chevrolet big block engine. (Thundercat’s was installed in a Schwan’s Ice Cream truck).

For different applications Allison offers different transmission modulators and governors, as well as different valve body components and settings. Upon returning from SV 2022 I sought out the advice of the local Allison dealer/distributor/service center, Smith Power Products. Scott and I have been there multiple times and when we walk in…the parts guy covers his head. We are that well liked! Seriously though, they have been very helpful and the parts guy suggested I talk with the AT545 guru who has been at Smith for many years.

"Way back when" I spoke with Tucker, and after talking with the fellow Tucker worked with at the Allison dealer/distributor/service center near them, I purchased a modulator “plug” from Tucker. It’s a fixed, but adjustable mechanical modulator. In a conversation with Smith's night shop foreman he was decidedly against the modulator plug concept. He explained the AT545 was similar to some larger Allison transmissions, and in those transmissions when the modulators failed it almost always wiped out either first or fourth gear. So a few of their customers would install a fixed modulator plug in lieu of the normal modulator and that “solved" the problem. However, that also resulted in very harsh shifts. (We can confirm Thundercat's transmission shifts harshly.) The AT545 guru I mentioned recommended we start by replacing the modulator plug with an Allison “soft shift” vacuum modulator (Allison part number 29501199).

I’ve got one coming and we’re supposed to install that and report back on how it works. The next step may be to change the transmission’s governor. Allison makes three different governors for the AT545. One is for gasoline engines and the other two are for Diesels. (The difference in the Diesel governors being the engine's maximum RPM.) I took the three transmission serial numbers and looked them up on Allison’s my transmission website. Interestingly, the governor in the 1544’s transmission is the gasoline engine governor, but both of the other transmissions have the higher RPM Diesel engine governor.

Valve body adjustments may also be required. There are adjusting collars installed in front of the springs, and repositioning the adjusting collar will increase or decrease the RPMs at which the transmission shifts. (IIRC each notch in the adjusting collar makes roughly a 50-60 RPM difference in the shift point.) But if that isn’t enough, new springs may be required. There are also trimmer valves which might require some tweaking. The night shop foreman I mentioned said “... if one spends the time to fine tune the transmission, it can be adjusted to shift as smoothly as a car”. I’m a bit skeptical of that, but I believe we can significantly improve the shifting characteristics for our applications.

I know Tucker installed AT545s behind several different engines and in different snowcat models. As the time involved to get the configuration and adjustments right can be significant, I suspect they didn’t spend a whole lot of time refining the setup for any of them. That would also suggest there's room for improvement on our part.

Thanks, great info BFT,

I'll definitely be looking forward to your results, as of course I learned mine isn't exactly 'optimum' either.

I'll definitely be looking forward to your results, as of course I learned mine isn't exactly 'optimum' either.

As a preliminary report on the modulator change, I can say the initial impression from driving the machine around the yard after installing the new Allison “soft shift” modulator was promising. Unfortunately, installing it was a bit of a PITA. The modulator is located at exactly the level of the Tucker’s lower truss frame member and there isn’t sufficient room to install it without moving the transmission a bit. That entailed unbolting the transmission mounts from the frame and with some “gentle persuasion” moving it enough to slip the modulator in position. But after the transmission is back in place there is precious little room to install the vacuum line on the modulator's vacuum fitting. A little research showed Dorman makes a 90º rubber vacuum elbow with a sharp 90º bend. (It's P/N 47092.) To install it, one needs to cut a little over an inch from one leg of the fitting and it barely fits inside the frame. That is then plumbed to a fitting installed on the intake manifold for a vacuum source.

We need to take the machine out for real world testing in snow with the transmission up to full operating temperature to see if other changes are required. But at this point we plan to install this same modulator on both Putri-Zilla and the 1544.

As some additional information, Allison introduced the “soft shift” modulator in 1989 as a service part, and from what I understand was never factory installed in transmissions. Allison colors their modulators, and this one is purple (it’s almost as ugly as Putri-Zilla’s BSG color). Googling the 29501199 part number provides links to various aftermarket modulators identified with that part number (as well as others) and a description as a “white stripe adjustable modulator”. The genuine Allison 29501199 modulator is not adjustable. I think the white strip adjustable modulator came out in 1972, so other than the fact that it presumably fits, I can’t see it having the same functionality as the real Allison 29501199 soft shift modulator. Another potential issue is the adjustment. My understanding is the adjusting screw is accessed through the vacuum fitting on the end of the modulator. With so little room between the vacuum fitting and the frame... good luck with that.

We've also been knocking out some re assembly tasks on Putri-Zilla, such as installing the hydraulic tank, installing the push-pull cables for the heater/defroster control and the temperature control valve, and Scott has been developing a plan for mounting the transmission shifter cable on the transmission end. The system on Thundercat works well and is much simpler than the method Tucker used on the 1544. I think we’ll try and replicate what we did on Thundercat. It’s amazing, and sad, that though we performed that very same task a few years ago, neither of us remember exactly what we did. We need to get this machine done before senility overcomes us and we become blithering idiots…though some might think we’re there already!

We need to take the machine out for real world testing in snow with the transmission up to full operating temperature to see if other changes are required. But at this point we plan to install this same modulator on both Putri-Zilla and the 1544.

As some additional information, Allison introduced the “soft shift” modulator in 1989 as a service part, and from what I understand was never factory installed in transmissions. Allison colors their modulators, and this one is purple (it’s almost as ugly as Putri-Zilla’s BSG color). Googling the 29501199 part number provides links to various aftermarket modulators identified with that part number (as well as others) and a description as a “white stripe adjustable modulator”. The genuine Allison 29501199 modulator is not adjustable. I think the white strip adjustable modulator came out in 1972, so other than the fact that it presumably fits, I can’t see it having the same functionality as the real Allison 29501199 soft shift modulator. Another potential issue is the adjustment. My understanding is the adjusting screw is accessed through the vacuum fitting on the end of the modulator. With so little room between the vacuum fitting and the frame... good luck with that.

We've also been knocking out some re assembly tasks on Putri-Zilla, such as installing the hydraulic tank, installing the push-pull cables for the heater/defroster control and the temperature control valve, and Scott has been developing a plan for mounting the transmission shifter cable on the transmission end. The system on Thundercat works well and is much simpler than the method Tucker used on the 1544. I think we’ll try and replicate what we did on Thundercat. It’s amazing, and sad, that though we performed that very same task a few years ago, neither of us remember exactly what we did. We need to get this machine done before senility overcomes us and we become blithering idiots…though some might think we’re there already!

Work continues on Putri-Zilla. Nothing really earth-shattering in terms of progress, more of finishing up various tasks to complete sections of the overall project.

While The Infamous WBJ1 tries to cultivate an image of being “sweet” I can assure you he thoroughly enjoys poking the bear (me) at just about every opportunity. With that background, I had an idea I was very tempted to follow through on, but in a moment of weakness…didn’t. Here’s the story:

The engine in Putri-Zilla is a GM LS series engine and it has a “drive by wire” gas pedal as opposed to a “drive by cable” old-school mechanical system. The “drive by wire” setup uses an electronic gas pedal that sends signals from a module to the engines computer, which in turn provides input to the throttle body. Of course GM designed this pedal to work with the firewall and floor setup in the vehicles they installed the engine in. Naturally, those are different than what Tucker built in Putri-Zilla. When Scott and I positioned the gas pedal’s mounting pad on Putri-Zilla’s firewall, the pedal itself was restricted from its full motion. That meant we would need to fabricate a bracket.

But…what if we made a bracket that allowed some, but not full pedal travel. I could picture The Infamous WBJ1…foot to the floor and getting passed by…everything. It was a pleasing (to me) image, but as much fun as that would be, we built a bracket that allows full pedal travel. Yup…a missed opportunity to get a little poking in of my own.

Here’s a pic of the bracket to space the gas pedal out from the firewall.

And here's the pedal and bracket installed.

While the wiring has been just about complete for some time, we hadn’t connected the batteries, or installed the battery separator. So we made a list of what we needed and I went to a small company in SLC that carries a good selection of automotive related wire and supplies. Not a big list, and I was expecting it to cost $40, or so. Hah! I was stunned. Here’s the stuff. That’s 4 gauge wire, various copper lugs and some heat shrink tubing…almost $90 worth.

I think future projects are going to cost significantly more money to complete, and BTW Tucker, Inc just raised their parts prices by 5% on April 1.

Here’s the vehicle battery and battery separator (to the left of the master cylinder). The vehicle battery is grounded to the engine, and there is another grounding cable from the engine to the frame. The center terminal on the battery separator is connected to the alternator. The left terminal is connected to the winch battery and the right terminal connects to both the vehicle battery and the vehicle wiring harness circuit breaker, just above the battery in the photo.

We also installed the winch, and that involved another trip to get some 2 gauge wire to connect it to the winch battery. After installation we tested the winch, and it works great.

Last night we installed new parking brake shoes along with the parking brake assembly, transmission output flange and parking brake drum. Scott took measurements and I can get a custom driveshaft made for the transmission to transfer case interface.

Scott has just about finished modifying the transmission mounted shift cable bracket, and then we’ll need to get a new cable made up after determining the required length.

Some slow, but steady progress....

While The Infamous WBJ1 tries to cultivate an image of being “sweet” I can assure you he thoroughly enjoys poking the bear (me) at just about every opportunity. With that background, I had an idea I was very tempted to follow through on, but in a moment of weakness…didn’t. Here’s the story:

The engine in Putri-Zilla is a GM LS series engine and it has a “drive by wire” gas pedal as opposed to a “drive by cable” old-school mechanical system. The “drive by wire” setup uses an electronic gas pedal that sends signals from a module to the engines computer, which in turn provides input to the throttle body. Of course GM designed this pedal to work with the firewall and floor setup in the vehicles they installed the engine in. Naturally, those are different than what Tucker built in Putri-Zilla. When Scott and I positioned the gas pedal’s mounting pad on Putri-Zilla’s firewall, the pedal itself was restricted from its full motion. That meant we would need to fabricate a bracket.