-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1973 Tucker Sno Cat 1443 New to Me

- Thread starter Track Addict

- Start date

Track Addict

Bronze Member

Merry Christmas!

Santa producing rollers and bearings out of chocolate at the North Pole production facility.

Santa producing rollers and bearings out of chocolate at the North Pole production facility.

Track Addict

Bronze Member

Took the pinion seal out this evening. Was concerned about getting the nut off but turns out is was loose already to the point the u joints were hitting. Little grinding and it came right off.

The cat would make a weird noise when not under power coasting down real step hill that I haven’t figured out . Under power the torque of the drivetrain must hold the pinion tight but when coasting it could unload.

Very little metal on the magnetic so hopeful there isn’t wear on the backside shims causing the bearing to be too tight. Only real way is to take out the third member which sucks.

Going to replace the nut torque and hope for the best! Probably remove the tracks and see how it feels rotating.

The cat would make a weird noise when not under power coasting down real step hill that I haven’t figured out . Under power the torque of the drivetrain must hold the pinion tight but when coasting it could unload.

Very little metal on the magnetic so hopeful there isn’t wear on the backside shims causing the bearing to be too tight. Only real way is to take out the third member which sucks.

Going to replace the nut torque and hope for the best! Probably remove the tracks and see how it feels rotating.

Track Addict

Bronze Member

Looks like this is actually a Dana 60 1310 29 spline pinion yoke installed in the 741 case.

Track Addict

Bronze Member

Here is the rear which is correct. Without measuring I bet the Dana 60 which fits the 741 is a shorter dimension allowing the nut to protrude and interfere with ujoints.

This probably more common replacement in later service events. Being loose still doesn’t make sense.

This probably more common replacement in later service events. Being loose still doesn’t make sense.

Track Addict

Bronze Member

S55 was the original build sheet spec which is also Dana 1310 and modern #7260. All interchange.

Issue here seems to be loose nut which seems to have backed off over time then when the cat got into extreme articulation drive shaft it hit the nut peened it over and it stuck there for who knows how long.

This has been the mystery noise.

Issue here seems to be loose nut which seems to have backed off over time then when the cat got into extreme articulation drive shaft it hit the nut peened it over and it stuck there for who knows how long.

This has been the mystery noise.

Blackfoot Tucker

Well-known member

I have zero experience with Dodge corporate axles, but it's just amazing to me the pinion nut backed off. My recollection is the Dana 60 pinion nut torque is on the order of 250 foot pounds, or so. That's a pretty good pull, and beyond the capability of many torque wrenches. But you also have the issue of preventing the pinion from turning as you torque the nut.

I'm not looking at one as I type this, but my recollection is the nut itself is a one-time use item, and it is a "deformed thread" nut. Those don't come loose. The nut pictured in the thread looks like a regular nut. I'm wondering if at some point in the past a previous owner used the wrong type nut?

I'm also wondering if the loose nut caused any damage to the bearings and/or the ring and pinion gears? Lastly, does the Dodge axle use a crush sleeve?

I'm not looking at one as I type this, but my recollection is the nut itself is a one-time use item, and it is a "deformed thread" nut. Those don't come loose. The nut pictured in the thread looks like a regular nut. I'm wondering if at some point in the past a previous owner used the wrong type nut?

I'm also wondering if the loose nut caused any damage to the bearings and/or the ring and pinion gears? Lastly, does the Dodge axle use a crush sleeve?

Track Addict

Bronze Member

489 case used a crush sleeve. 741 742 and Dana’s used shim packs. Eliminator kit for the crush sleeve is the way to go if you need to service a 489.

Today as I looked at the back drive and photos from history, the nut was at least tighter when I rebuilt the carriers because I painted over the nut which moved since then over a few hundred miles.

The yoke is not original and was replaced in life for some reason before I got it. Some online guidance suggests a much lower torque than the recommended 285 lbs.

Third member does not look to have been taken off before I got in there. Never thought to check the torque but just the opposite is that looks like PIA.

No metal and light shavings on magnetic drain plug.

Haven’t check the measurements yet but also possible the Dana yoke has interference from different dimension compared to s55 no longer available. That connection can seen strange ujoint angles.

Oil leak probably from the movement and a blessing in disguise.

Today as I looked at the back drive and photos from history, the nut was at least tighter when I rebuilt the carriers because I painted over the nut which moved since then over a few hundred miles.

The yoke is not original and was replaced in life for some reason before I got it. Some online guidance suggests a much lower torque than the recommended 285 lbs.

Third member does not look to have been taken off before I got in there. Never thought to check the torque but just the opposite is that looks like PIA.

No metal and light shavings on magnetic drain plug.

Haven’t check the measurements yet but also possible the Dana yoke has interference from different dimension compared to s55 no longer available. That connection can seen strange ujoint angles.

Oil leak probably from the movement and a blessing in disguise.

Track Addict

Bronze Member

This is what we call no bueno. Got new nut and tightened yoke back on to see.

Something has failed on the other side to allow this play and let the nut back off and hit like that. Guess hope wasn’t the fix.

Will drop tracks pull axles next few nights. Not horrible if the chunk clears the table.

Up to 4 non-self-propelling Tuckers at the East Coast Preserve!

Something has failed on the other side to allow this play and let the nut back off and hit like that. Guess hope wasn’t the fix.

Will drop tracks pull axles next few nights. Not horrible if the chunk clears the table.

Up to 4 non-self-propelling Tuckers at the East Coast Preserve!

Last edited:

Track Addict

Bronze Member

Single tracks in the mean time!

7/8/11 on the right. Dads could only dream about machines like that in the 80’s.

P

P

p

p

7/8/11 on the right. Dads could only dream about machines like that in the 80’s.

Last edited:

Track Addict

Bronze Member

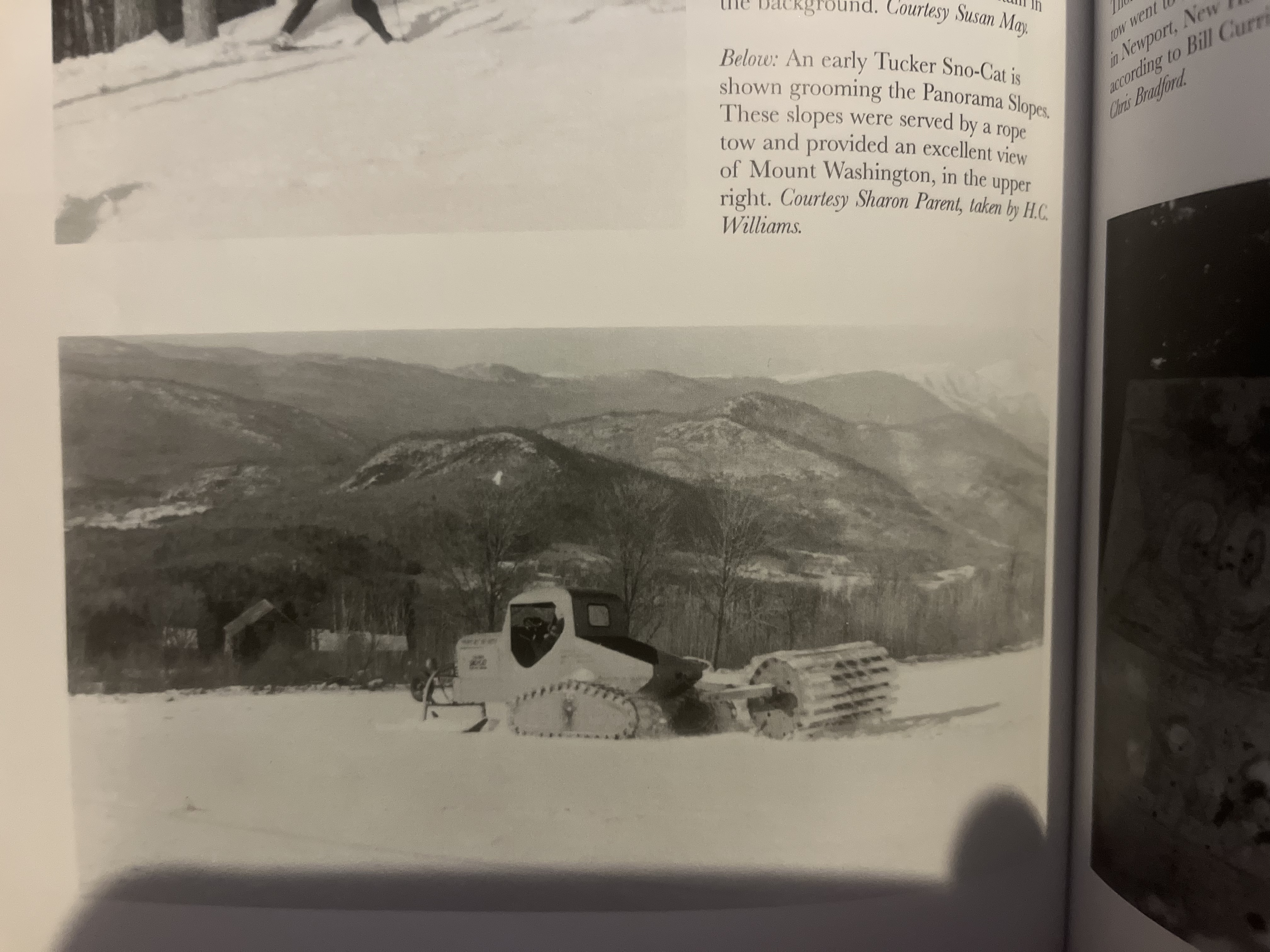

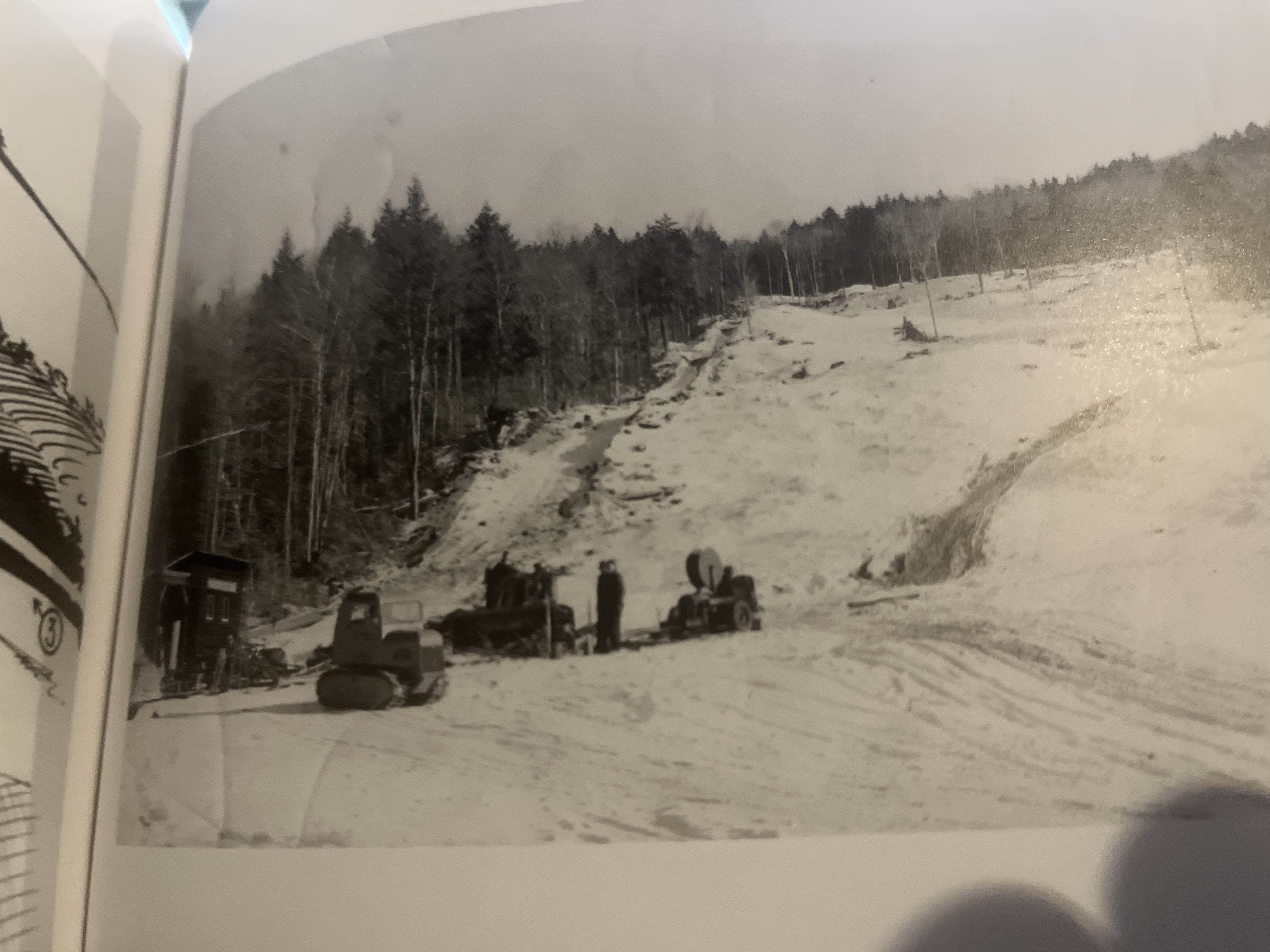

Those photocopy infringed pictures were in a book I was reviewing at a new concept in NH:

Bar/ski tune/board tune/ bike tune/ bar/cool

Pro Tune Glen NH. Kid friendly wife unofficially approved!

Bar/ski tune/board tune/ bike tune/ bar/cool

Pro Tune Glen NH. Kid friendly wife unofficially approved!

Track Addict

Bronze Member

No surprises yet. Passenger side hub loose.

Bearing tape has held and performed well for the few hundred miles. One of the inside journal adhesive failed but it seems to have stayed in place and performed.

Bearing tape has held and performed well for the few hundred miles. One of the inside journal adhesive failed but it seems to have stayed in place and performed.

Track Addict

Bronze Member

Anybody swap to green bearings in a Tucker 8 3/4?

No end play adjustment and it’s sloppy. The sprocket on pontoon or carrier float but my experience on a number of machines is the axles races float needing shims and lets the sprockets float.

Seems like a better bearing upgrade option.

No end play adjustment and it’s sloppy. The sprocket on pontoon or carrier float but my experience on a number of machines is the axles races float needing shims and lets the sprockets float.

Seems like a better bearing upgrade option.

olympicorange

Active member

some of these used a '' pilot or pocket'' brg. , on the end of the pinion for support. if so, very common to fail. if not , most probable would be the ''inner'' pinion brg. either way, disassembly is required. as far as the ''pinion nut'' goes, usually a ''crimp or lock ''nut.This is what we call no bueno. Got new nut and tightened yoke back on to see.

Something has failed on the other side to allow this play and let the nut back off and hit like that. Guess hope wasn’t the fix.

Will drop tracks pull axles next few nights. Not horrible if the chunk clears the table.

Up to 4 non-self-propelling Tuckers at the East Coast Preserve!View attachment 159639

most rebuilders replace with new each time. but they can be reused , with the use of ''loctite'' ... the threads get worn, sloppy... inside the nut,...or the pimion threads,... so they loosen up.....

Track Addict

Bronze Member

Final answer.

This cat lost a ring and pinion and yoke at some point looking at the markings and paint marker numbers.

Nut was reused and/or not tightened correctly. Not loosened up over time. Outer bearing slid up shaft and won’t seat correctly now on shaft. Looks real good.

New outer pinion bearing, shim pack, and proper adjustment/torque should be good to go!

This cat lost a ring and pinion and yoke at some point looking at the markings and paint marker numbers.

Nut was reused and/or not tightened correctly. Not loosened up over time. Outer bearing slid up shaft and won’t seat correctly now on shaft. Looks real good.

New outer pinion bearing, shim pack, and proper adjustment/torque should be good to go!

Track Addict

Bronze Member

Chunk just clears with the pivot bolt out. If I hung the axle by jacking the frame would have had more clearance.

Few marks on here from something. Few parts and back together.

Few marks on here from something. Few parts and back together.

Track Addict

Bronze Member

Still haven’t figure this preload issue out. Pretty sure these 456 gears had to have come out of a 489 case. Don’t think the 741 case came with 456 or a 29 spline. Tucker must have needed that gear change.

Whatever the issue is the bearing races and the items between pictured are not letting the preload occur and bearings sit in the races for some reason TBD.

Note the metal pitting on the inner pinion bearing inner race.

Whatever the issue is the bearing races and the items between pictured are not letting the preload occur and bearings sit in the races for some reason TBD.

Note the metal pitting on the inner pinion bearing inner race.

chowderman

Well-known member

the 'pitting' is not 'pitting' - it is damage from metal particles floating through the bearing - carried by the lube.

something in the unit 'ate' itself, produced metal bits.

is there a magnet plug/trap installed?

something in the unit 'ate' itself, produced metal bits.

is there a magnet plug/trap installed?

Track Addict

Bronze Member

Yes. I think this is a used pinion that was installed in life or lazy service before me of something did fail that bearing didn’t make the cut to be replaced.

Nothing else has that that wear. I have been in here a few hundred miles ago and installed magnetic drain plug with normal fine shavings.

Nothing else has that that wear. I have been in here a few hundred miles ago and installed magnetic drain plug with normal fine shavings.

sledhead Ed

Member

If you're talking preload on the pinion set up and don't have preload change the shim thickness. Most pinion preload is inch pounds rotations wise. meaning measure inch pounds of pressure while rotating the pinion by the pinion nut after full torque. The pitted inner part of the bearing surface is pretty common on bad pinion bearings. I just did bearings in my brothers rearend in his truck. One pinion bearing pitted worse than that.

Only symptom on the truck had a whine in rearend on acceleration

Only symptom on the truck had a whine in rearend on acceleration

Track Addict

Bronze Member

That’s the problem. With all the shims out the bearings are not seated in the race at torque spec.

Hear a video. Does this even with yoke back on and torqued.

Hear a video. Does this even with yoke back on and torqued.

sledhead Ed

Member

The big spacer on the bottom(wide) is to set your pinion height that has stay between bearing and pinion. If you're saying that taking out the two small shims and leaving the long tube spacer in and have too much Freeplay / space, then either the tube spacer is wrong or the case is worn where the outer races install. so now you have to find out if your pinion height is correct. which can be done with just the lower bearing and shim in place. then measure the height. it's a little harder to do holding the pinion in place while trying measure with only one bearing installed. then when your height is determined to be right. then you have to figure out if long spacer is right or need to be machine because of case wear but all of this needs to be done with new bearings not old ones. or you might have to shim the bearing race to case at the yoke end. the pinion height is critical that needs to be right for your backlash and wear and tooth depth. Also when wrong will make noise on Decelerating or accelerating and break gears easily.

sledhead Ed

Member

pinion height is your first set up then torque pinion nut to check preload and rotation torque. Then backlash then tooth pattern

Track Addict

Bronze Member

I am comfortable with all that. Going to start new bearings spacers and see. May end up at a shop.

sledhead Ed

Member

call me if you run into any problems. also got boxes of spacer from rearends over the years can match some up. if you need some

Blackfoot Tucker

Well-known member

I don't know if this will interest you, but I'll throw it out there just in case. (What's also true is at some point in the future someone may be reading your thread, and this may help them.)

There is a Canadian fellow named Bill Ansell who does a deep dive into many different areas, and I have found his work on multiple topics extremely educational and helpful. He goes by the name BillaVista, and his work first appeared on pirate4x4.com, but now he has his own website, unsurprisingly, billavista.com.

Here's a link to his discussion of ring and pinion gears, in this case on the Dana 60, but many of the principles have universal application. He really goes far in depth, and does an excellent job of presenting the information.

This won't be a quick read, so grab a couple of your favorite beverages and dig in - if you so choose:

There is a Canadian fellow named Bill Ansell who does a deep dive into many different areas, and I have found his work on multiple topics extremely educational and helpful. He goes by the name BillaVista, and his work first appeared on pirate4x4.com, but now he has his own website, unsurprisingly, billavista.com.

Here's a link to his discussion of ring and pinion gears, in this case on the Dana 60, but many of the principles have universal application. He really goes far in depth, and does an excellent job of presenting the information.

This won't be a quick read, so grab a couple of your favorite beverages and dig in - if you so choose:

BillaVista.com-Gear Setup Bible Tech Article by BillaVista

www.billavista.com

sno-drifter

Bronze Member

This is a fine reference. What it does not cover is how to set pinion depth if you do not already have the pinion in the housing. A whole nuther ball of wax. What I have done in this case is turn a round cylinder, the diameter of the carrier bearings and make a machined block to go between the end of the pinion and the turned cylinder which is a few thousandths undersize . Secure the cylinder with the bearing caps. Then use feeler gages to set the proper depth using the scribed + or - on the pinion to set the depth. I always go with the scribed depth and have not had a howler or failure. A real good description of Dana gear set up.I don't know if this will interest you, but I'll throw it out there just in case. (What's also true is at some point in the future someone may be reading your thread, and this may help them.)

There is a Canadian fellow named Bill Ansell who does a deep dive into many different areas, and I have found his work on multiple topics extremely educational and helpful. He goes by the name BillaVista, and his work first appeared on pirate4x4.com, but now he has his own website, unsurprisingly, billavista.com.

Here's a link to his discussion of ring and pinion gears, in this case on the Dana 60, but many of the principles have universal application. He really goes far in depth, and does an excellent job of presenting the information.

This won't be a quick read, so grab a couple of your favorite beverages and dig in - if you so choose:

BillaVista.com-Gear Setup Bible Tech Article by BillaVista

www.billavista.com

Track Addict

Bronze Member

Thanks to the reality check from the knowledge base here diff is at the professionals. They showed me wear I couldn’t see.

Will be back good as new soon!

Will be back good as new soon!

Track Addict

Bronze Member

Diff all rebuild and just got some fresh bearing tape from VT.

YamaDooPolCat

Well-known member

I was surprised that your tucker has a different differential than mine. The guy at the driveline shop said the Dana 60 that I have in my 1544 is one of the most difficult and time consuming differentials to set up. They don't even like doing these ones at the shop.

You start with the pinon and pull it apart REPEATEDLY and change shims until you get the correct in/lbs drag, then move on to the crown and carrier.

I made up a wood bench that just fits under the housing so the carrier could just barely be rolled out onto the bench and not fall on me. They also loaned (beer) "set up" bearings that are honed out to be able to slide off and on the carrier so the next shim trial can be done without wrecking the carrier bearings. I wrote down each shim change and the results, because it is extremely easy to get lost on what is going on with the work involved with each change. No beer break on this job.

I also used the old pinon nut until the final assembly.

Setting up my Dana 60 took three days because I had to take a break after a while, and I'm still going to hold my breath! I'll drop the pan after the first 5 hours and see what the oil looks like.

![image11[2].jpeg image11[2].jpeg](https://www.forumsforums.com/attachments/image11-2-jpeg.160106/)

You start with the pinon and pull it apart REPEATEDLY and change shims until you get the correct in/lbs drag, then move on to the crown and carrier.

I made up a wood bench that just fits under the housing so the carrier could just barely be rolled out onto the bench and not fall on me. They also loaned (beer) "set up" bearings that are honed out to be able to slide off and on the carrier so the next shim trial can be done without wrecking the carrier bearings. I wrote down each shim change and the results, because it is extremely easy to get lost on what is going on with the work involved with each change. No beer break on this job.

I also used the old pinon nut until the final assembly.

Setting up my Dana 60 took three days because I had to take a break after a while, and I'm still going to hold my breath! I'll drop the pan after the first 5 hours and see what the oil looks like.