Yup for 2025!

-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1953 Tucker Sno Cat 443 Mt Washington WMTW Channel 8 Restoration

- Thread starter Track Addict

- Start date

This cassette ready to flip to side B.

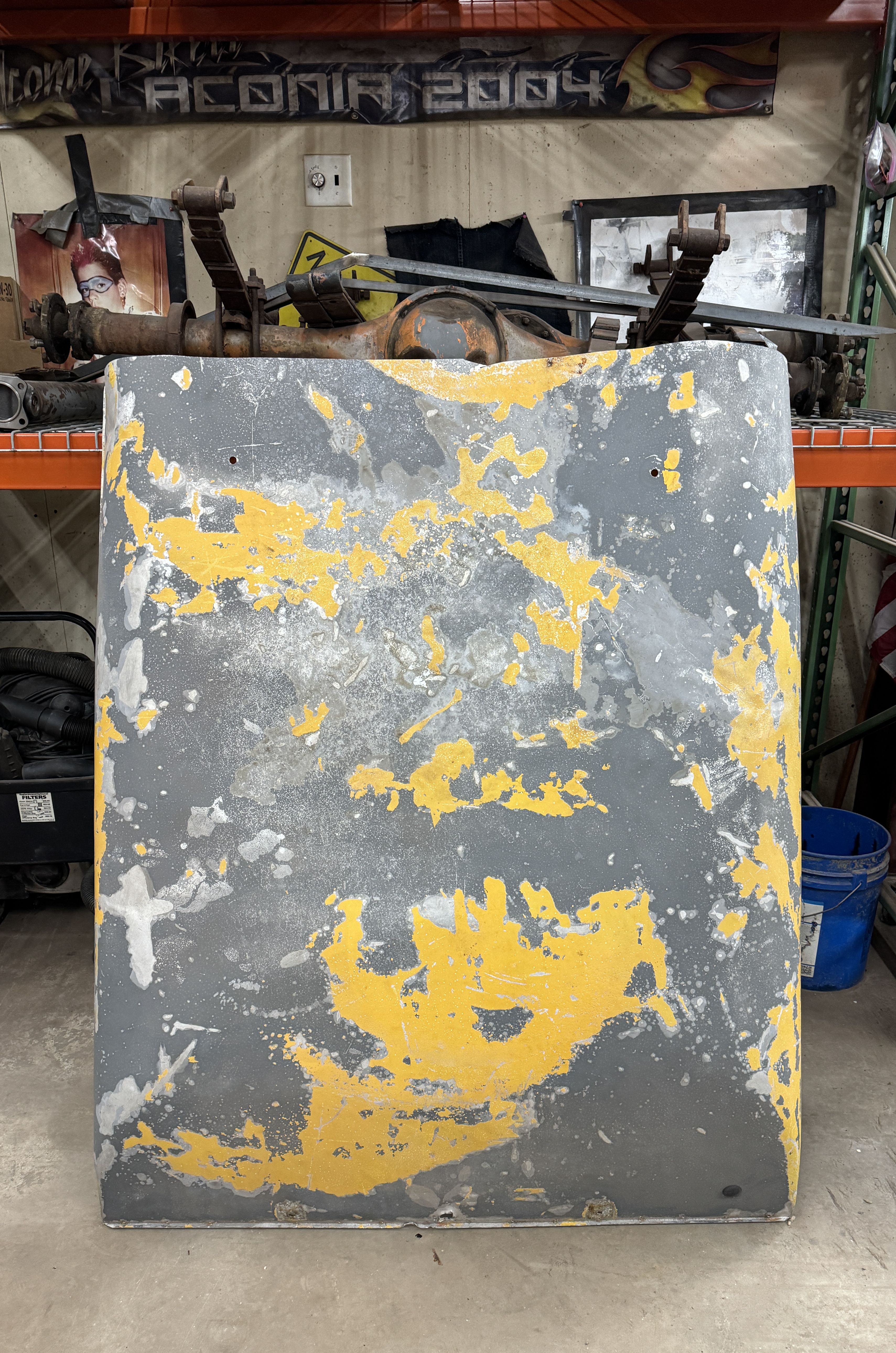

Took as much paint as I could get off with the power washer. This will be the final patina used for the preservation.

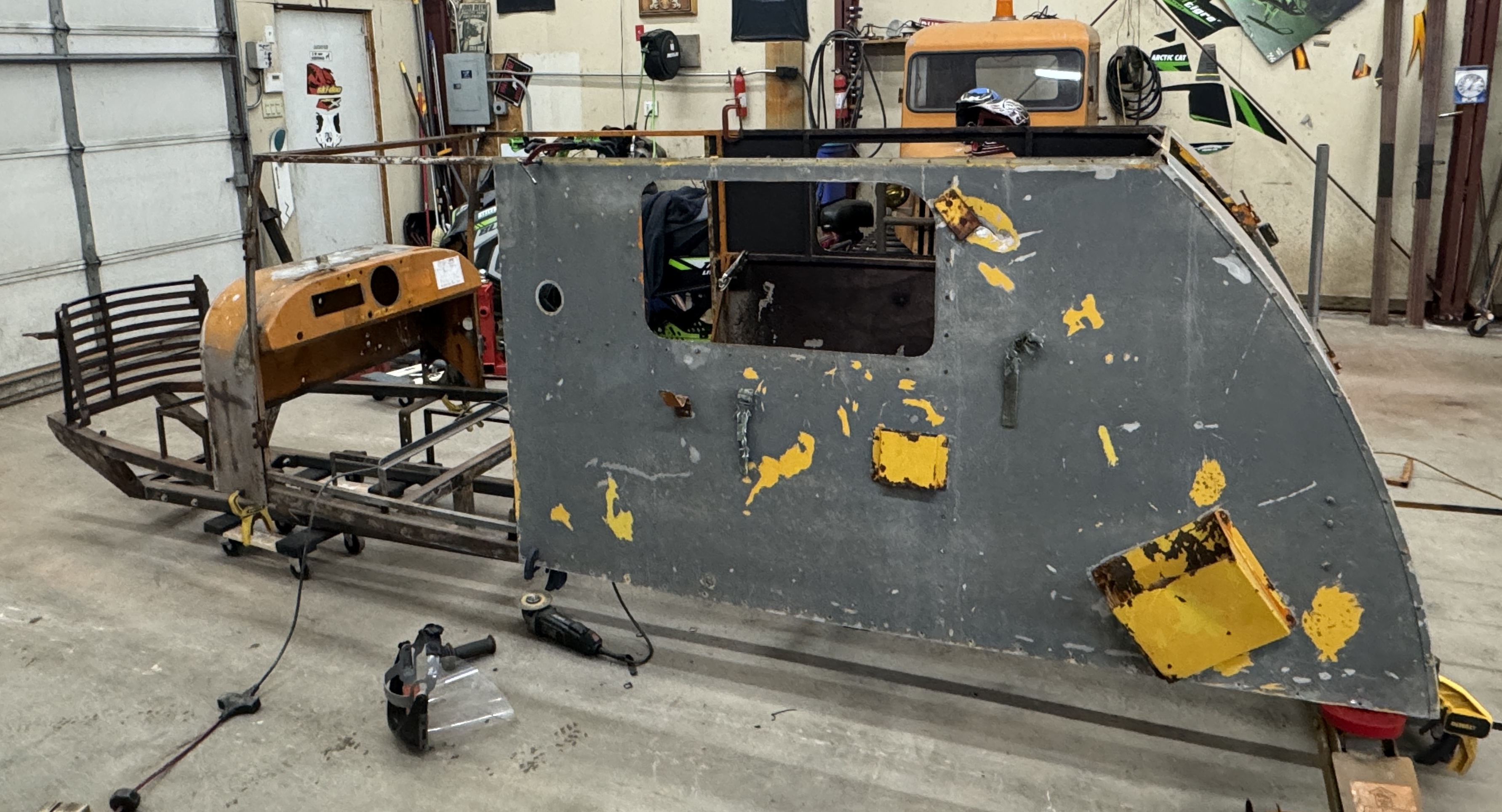

Got the roof banged out pretty good. Panels will need to come off eventually to get the frame right and blend the roof.

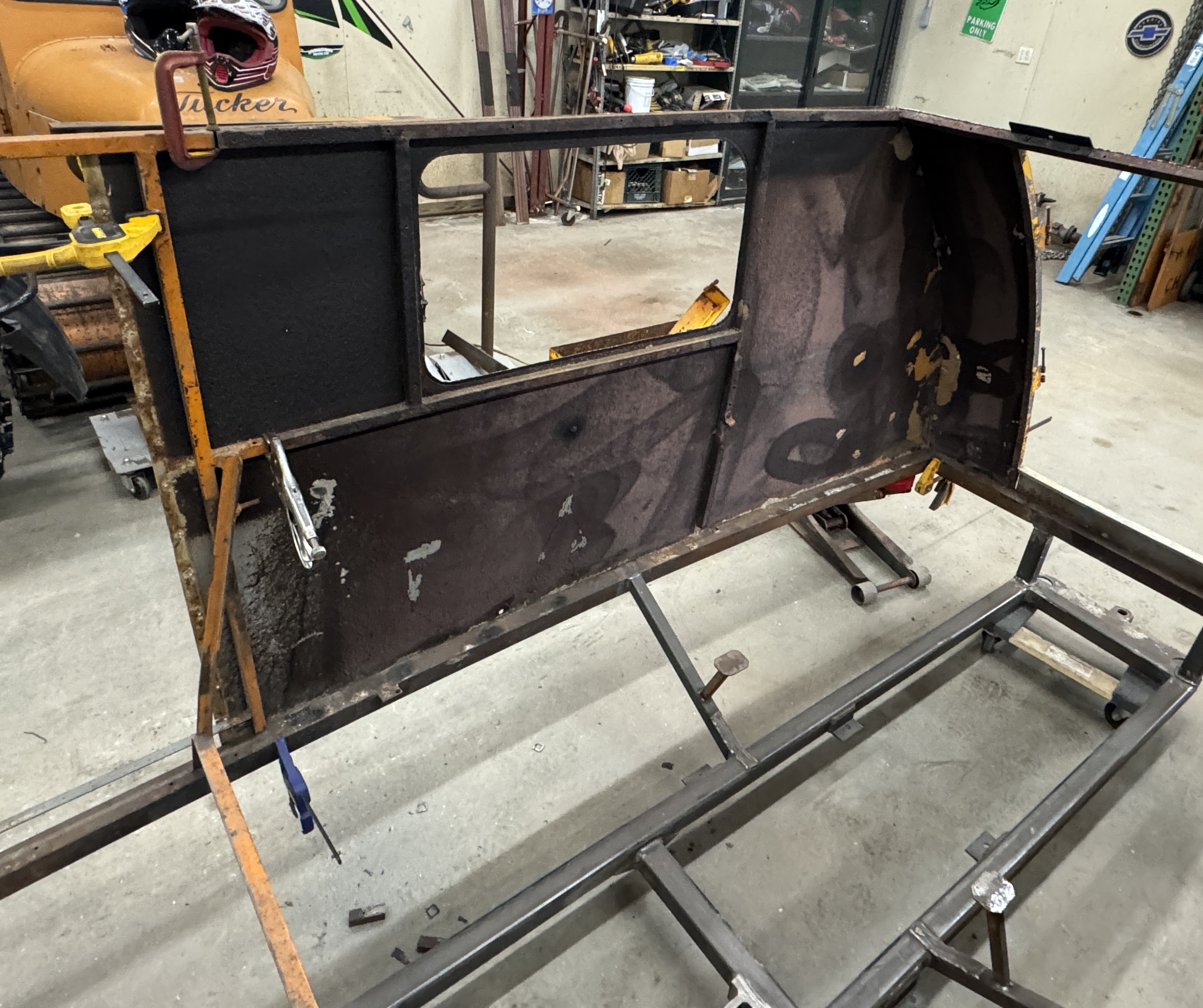

Inside panels will need a fresh coat of trunk paint on the donor. Pulled out all the old wiring and add ons. Have a pretty good idea on how I want the finishes for final assembly.

The body headed up top for storage as I focus on the mechanicals.

Got the roof banged out pretty good. Panels will need to come off eventually to get the frame right and blend the roof.

Inside panels will need a fresh coat of trunk paint on the donor. Pulled out all the old wiring and add ons. Have a pretty good idea on how I want the finishes for final assembly.

The body headed up top for storage as I focus on the mechanicals.

vintagebike

Well-known member

Historical accuracy update. Sometimes it’s what you know for sure that just ain’t so said a wise person before me.

Here is what looks to be a factory roof hoop. It’s is of Tucker quality or lack their of, paint matches, seems to support a roof rack it once had or snow load concerns atop Mt Wash, is currently on the machine, and has a matching patina.

Must be factory or maybe build no two the same which is a theory once pressed on the origins.

Here is what looks to be a factory roof hoop. It’s is of Tucker quality or lack their of, paint matches, seems to support a roof rack it once had or snow load concerns atop Mt Wash, is currently on the machine, and has a matching patina.

Must be factory or maybe build no two the same which is a theory once pressed on the origins.

The East Coast Preserve promotes being a good steward of historical accuracy to carry forward an amazing wealth of Tucker knowledge.

Sometimes the propriety historical trust fact checking tool puts forward some wisdom for your consideration….

Original photos of roof rack don’t line up where this hoop exists what’s it support of not the rack?

Did Tucker ever have a roof rack option from the factory?

Have you ever seen a hoop like that on any 443 photo of that vintage?

Why does the hoop line up perfectly where the body was cut off?

Why are there no welds on the body side of the frame like the rest of the body frame which is welded all 4 sides?

Why does that hoop have no grey primer/color where the paint is worn off like the rest of the body frame?

Could the 443 have been converted to a 442 long before the tracks are removed for a new purpose before the junkyard?

Why would a junkyard or anybody put that much work into painting the hoop to match very similar paint on it?

Why doesn’t under side of oe roof have spray paint if added after?

If you cut the body off at that location and didn’t add a support wouldn’t it now be very weak for snow load and side load?

But isn’t this a great mystery history to learn and perfect spot to seam the donor to OE roof?

You be the judge I follow the scientific experts!

Sometimes the propriety historical trust fact checking tool puts forward some wisdom for your consideration….

Original photos of roof rack don’t line up where this hoop exists what’s it support of not the rack?

Did Tucker ever have a roof rack option from the factory?

Have you ever seen a hoop like that on any 443 photo of that vintage?

Why does the hoop line up perfectly where the body was cut off?

Why are there no welds on the body side of the frame like the rest of the body frame which is welded all 4 sides?

Why does that hoop have no grey primer/color where the paint is worn off like the rest of the body frame?

Could the 443 have been converted to a 442 long before the tracks are removed for a new purpose before the junkyard?

Why would a junkyard or anybody put that much work into painting the hoop to match very similar paint on it?

Why doesn’t under side of oe roof have spray paint if added after?

If you cut the body off at that location and didn’t add a support wouldn’t it now be very weak for snow load and side load?

But isn’t this a great mystery history to learn and perfect spot to seam the donor to OE roof?

You be the judge I follow the scientific experts!

Forensics on the donor body indicate that this rear door featured a rare rear wiper?

Thinking by the looks is wiper arm was shut in the door many times outlined by the crushed roof flange. It would need to be lifted up to open and close and much like juggling in winter winds.

The sno build up on the rear door from a snow dust eventually caused the body tear as the wiper froze stuck and motor pivoted to the oblivious designer or operator.

Unknown history origin last known address on this cold case.

Thinking by the looks is wiper arm was shut in the door many times outlined by the crushed roof flange. It would need to be lifted up to open and close and much like juggling in winter winds.

The sno build up on the rear door from a snow dust eventually caused the body tear as the wiper froze stuck and motor pivoted to the oblivious designer or operator.

Unknown history origin last known address on this cold case.

my my my, TA, you have a very active imagination

Body mounted. Just need to add the bungy cords and twine.

This project hitting pause and pivoting back to the runners until the sno flies!

This project hitting pause and pivoting back to the runners until the sno flies!

I used to ride in that SnowCat back in 1959-1960 time frame. My father was a RF Engineer for WMTW and he would occasionally have to work up on the mountain transmitter In the winter. They always took the Tucker up the mountain and at that time WMTW also had a two track Bombardier with a plow on it to assist in keeping the road open for the Tucker. Wish I had more info but I had a picture my father took and sent it to Tucker a few year back validating it was this machine. This is a huge undertaking for a restoration and wish you the best and would love a chance to see it when done. Good Luck! Ken Knight, Augusta Maine

RIP Marty! I will take great care of your Tucker!

www.wmtw.com

www.wmtw.com

'Marty on the Mountain,' long-time WMTW employee, dies at age 86

His family says Marty Engstrom died at his home in Fryeburg Thursday afternoon.

This Tucker will be named “Marty” in honor of his great legacy at WMTW and atop MT. Washington.

Planning a tribute to him on the machine and looking forward to “Marty” returning to the summit!

Planning a tribute to him on the machine and looking forward to “Marty” returning to the summit!

Some interest in this cat has swirling around with the passing of Marty. Got a few pictures from WMTW today. Note the rear cab heater added. The OE heater was upgraded as well. Cold temps during service must have have required thee upgrade.

Other info provided is that Marty wouldn't have driven the cat but this was his transportation up and down. Trying to connect with the daughter of the operator for more history. Pretty cool!

Other info provided is that Marty wouldn't have driven the cat but this was his transportation up and down. Trying to connect with the daughter of the operator for more history. Pretty cool!

Marty is taking to the airwaves again this Sunday!

Will be online day or two after.

www.facebook.com

www.facebook.com

Will be online day or two after.

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

Here is a link to the segment:

https://www.wmtw.com/article/restor...ington-found-restored-marty-engstrom/46595499

https://www.wmtw.com/article/restor...ington-found-restored-marty-engstrom/46595499

This history just keeps coming thanks to the public support!

Looks like Loggah and I have an operator in common now…. Amazing read and wealth of missing history connected.

www.mtearchronicles.com

www.mtearchronicles.com

Looks like Loggah and I have an operator in common now…. Amazing read and wealth of missing history connected.

Alone on Mt. Washington

Phil Labbe's Years on the Mountain At 11:30 on the morning of December 16th, 1981, Phill Labbe decided to turn back. Seven miles up the Auto Road, a mile from the 6,288-foot summit of Mt. Washington, the fury of the “world’s worst weather” made further progress impossible. Constant...

www.mtearchronicles.com

www.mtearchronicles.com

Marty’s son reached out and will be sending me pictures as he finds them.

Here’s a detailed one. What do you think the pipe coming out the door is?

Here’s a detailed one. What do you think the pipe coming out the door is?

Aux gasoline heater.

Bennyboy1337

Active member

For what it's worth, my 64 has solid rod steel loops for roof support, and they're flimsy as well, which as a result means the roof has bent in over the years from snow load. Roof and cab frame design always seemed to be an afterthought from Tucker on these machines, there is no consistency between the years and they're all bare bones. Same goes for roof racks, I don't think there was ever a factory option for one, so there are hundreds of custom designs out there. My cat has about 30 holes in the roof from what were likely 3-4 different roof rack designs over the years.Why are there no welds on the body side of the frame like the rest of the body frame which is welded all 4 sides?

If I were to guess, there wasn't a set template for roof shells, so there was somehow inconsistency between cat to cat. This means the roof supports had to be custom fit for every cat, and as a result welded in place (hence the no welds on body side).

Like a full bar, one out one in!

Marty has moved back into primetime for the off season.

Marty has moved back into primetime for the off season.

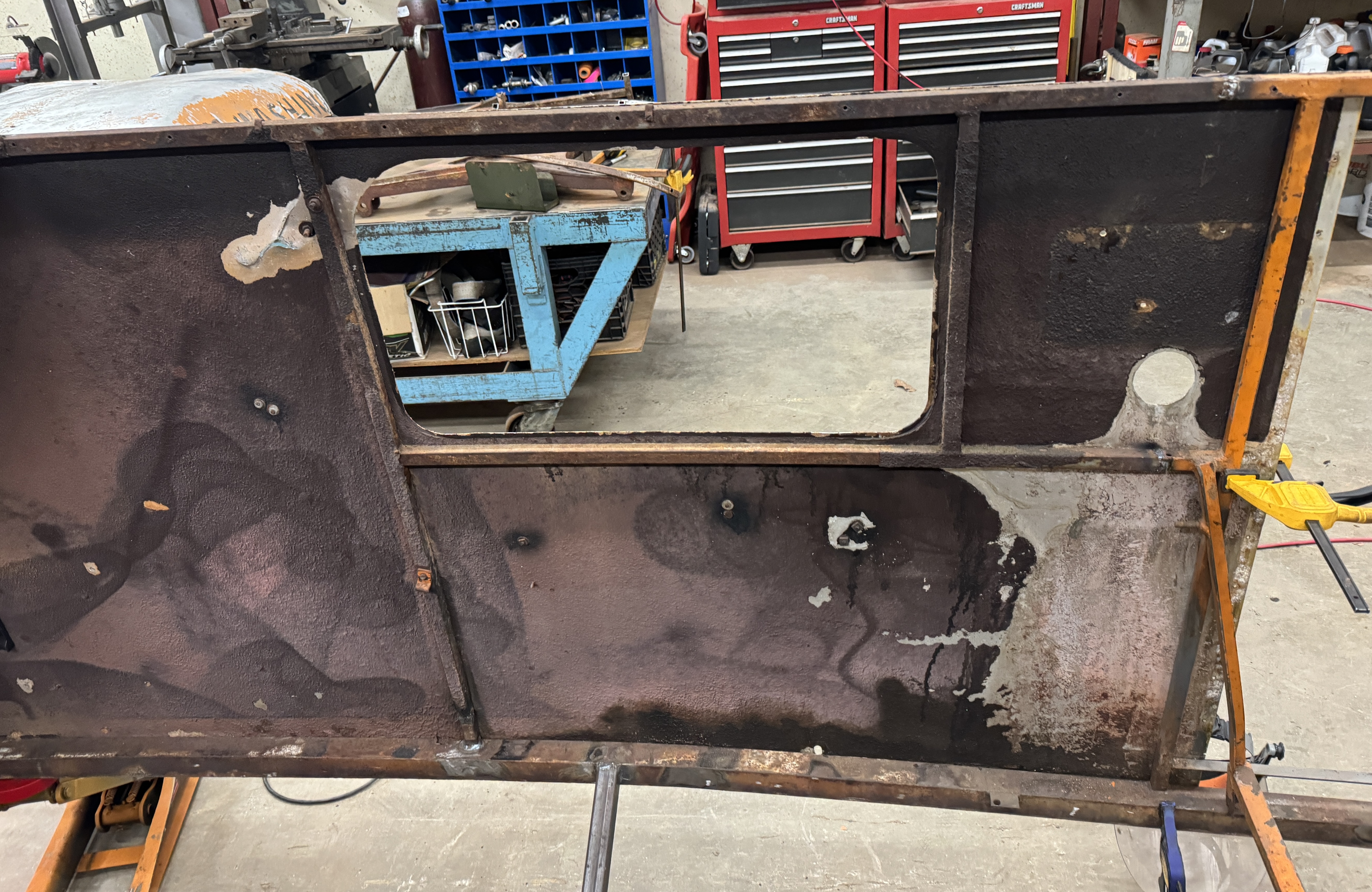

Did some preliminary body fitting and removed the roof from the donor body.

The roof hoop was added before interior paint and lines up with the roof rack. I believe there was a second one on the back. The way this rack carries weight up high as pictured would need to have support under. Holes match mounting.

Used the Rob Miller grass bag pound technique to take some dents out of the OE roof. Going to have to trim back a clean edge and lap it on the roof hoop which will need to move forward. Donor body has plenty material to work with.

Jovan Tucker on the roof support team this evening.

Going to leave the rest of the panels on for fit up and remove some frame on both pieces need to keep the OE door james and graft the frame between that and the window. Measurements are close so far. Plenty material to line up it appears.

The roof hoop was added before interior paint and lines up with the roof rack. I believe there was a second one on the back. The way this rack carries weight up high as pictured would need to have support under. Holes match mounting.

Used the Rob Miller grass bag pound technique to take some dents out of the OE roof. Going to have to trim back a clean edge and lap it on the roof hoop which will need to move forward. Donor body has plenty material to work with.

Jovan Tucker on the roof support team this evening.

Going to leave the rest of the panels on for fit up and remove some frame on both pieces need to keep the OE door james and graft the frame between that and the window. Measurements are close so far. Plenty material to line up it appears.

I was mistaken on the roof rack supports.

The fronts mounts were on the unsupported roof which is probably why the roof is dented here. You can see the marks from the threaded adjusting rods being too loose or too tight and the mount base.

The hoop was OE as shown by the unpainted roof underneath.

The fronts mounts were on the unsupported roof which is probably why the roof is dented here. You can see the marks from the threaded adjusting rods being too loose or too tight and the mount base.

The hoop was OE as shown by the unpainted roof underneath.

Big thanks to my friends across the  for the support on this project. Special shout out to Jinn, Jack, and Scott for organ donation and the flight for life getting the organs east!

for the support on this project. Special shout out to Jinn, Jack, and Scott for organ donation and the flight for life getting the organs east!

The biggest hurdle in this project was finding a body to graft in and fit without canabizing another. Well that day has come to fruition!

This cat suffered some roof and body trauma that just happens to compliment what was still good on Marty.

Moment of silent for this brave Tucker and the sacrifice for another…….

Tonight confirms the old Tucker addage, “build no two the same”

The biggest hurdle in this project was finding a body to graft in and fit without canabizing another. Well that day has come to fruition!

This cat suffered some roof and body trauma that just happens to compliment what was still good on Marty.

Moment of silent for this brave Tucker and the sacrifice for another…….

Tonight confirms the old Tucker addage, “build no two the same”

Luckily for me the difference is 2” of length. You can see the difference in the pics.

The body is a perfect type A match and officially turned back into a proper 443. Only modification needed will be to scribe and shear the door pillar on the skin to fit.

Perfect fit and all within Tucker tolerance. The putty knife trim backer was key!

The body is a perfect type A match and officially turned back into a proper 443. Only modification needed will be to scribe and shear the door pillar on the skin to fit.

Perfect fit and all within Tucker tolerance. The putty knife trim backer was key!

What are you talking about? Looks like it is lining up perfectly well within Tucker specs!!

Tacked in the frame which stiffened up the body nicely. Had to add some tube material on the down supports.

Once the body panels are removed will clean up and re weld all the splice areas. If you have ever welded on these old frames it a real treat to watch the metal disapear. Add little tar coating for good measure may be a few feathers.

Once the body panels are removed will clean up and re weld all the splice areas. If you have ever welded on these old frames it a real treat to watch the metal disapear. Add little tar coating for good measure may be a few feathers.

Last edited: