Jphoenix

Well-known member

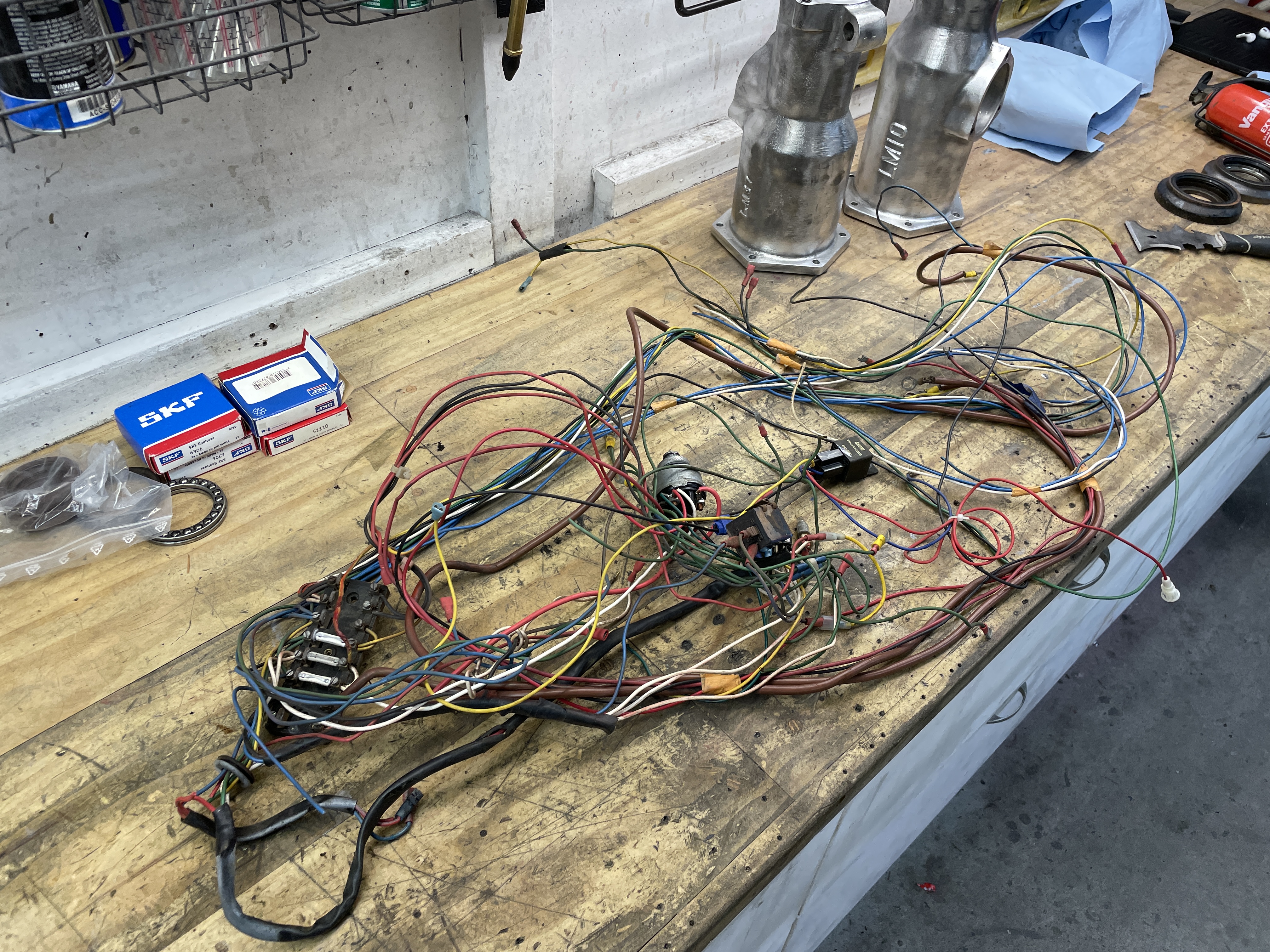

Engine mostly ready, waiting on a set of wires, the number 3 & 4 cylinder plug wires burnt through from lying on the exhaust riser. Explains the rough running a bit more. Pulled the wiring harness out, gonna put a Blue Sea fuse box in with all new wiring, plus a tach and an oil pressure gauge.

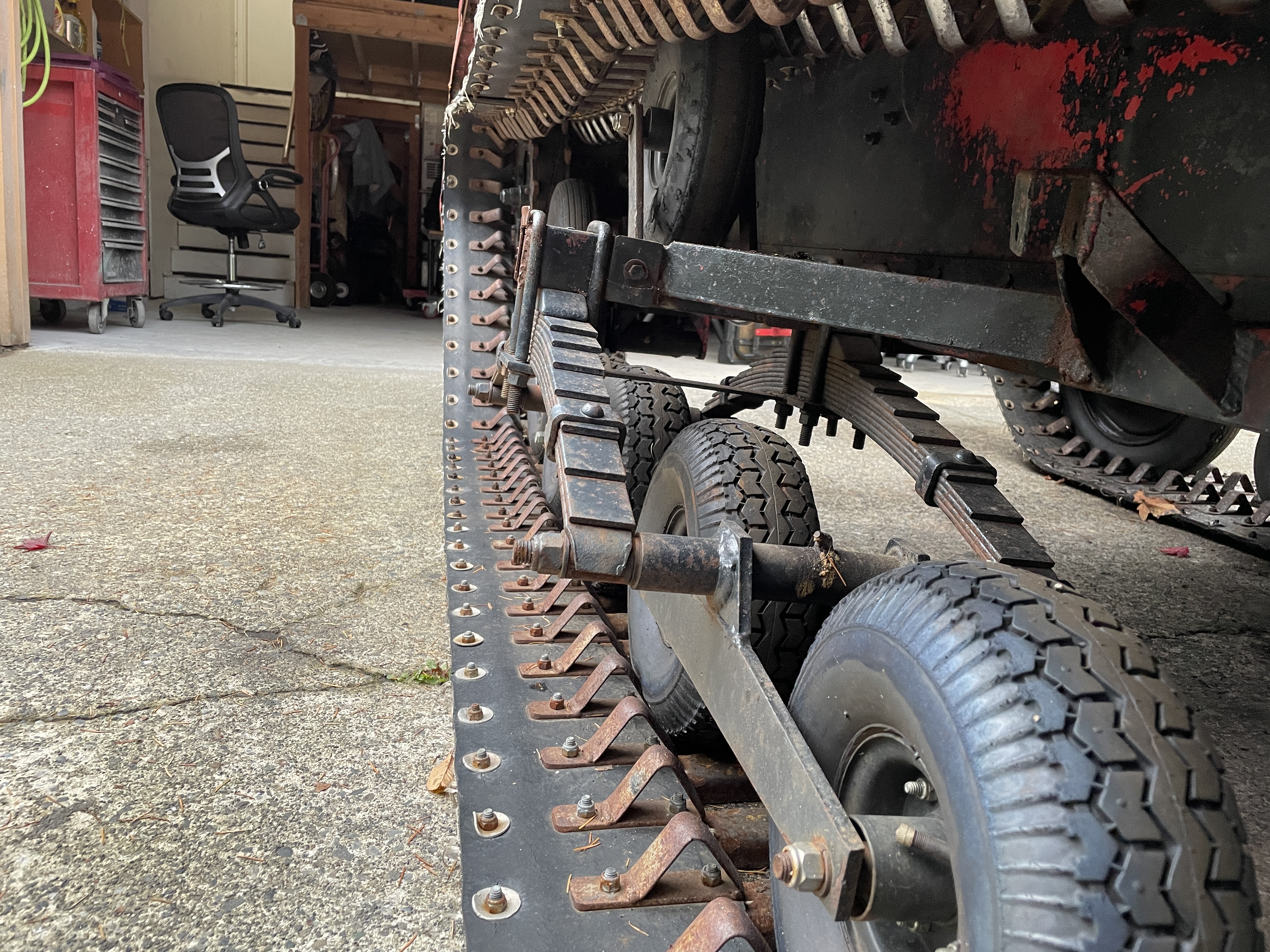

Frankie has a couple degrees list to the left, due to the left bogie mount being bent up a bit. I’ll get that all apart and rebuild it after I get the Variator back together and the engine back in.

Wiring harness in pretty sad shape, the old fuse box held the crappy VW/Lucas style fuses.

Frankie has a couple degrees list to the left, due to the left bogie mount being bent up a bit. I’ll get that all apart and rebuild it after I get the Variator back together and the engine back in.

Wiring harness in pretty sad shape, the old fuse box held the crappy VW/Lucas style fuses.