teledawg

Active member

Re: thrust bearing

It looks like the bottom race is missing. No wonder the thrust bearing failed! Cast iron is not a very good bearing race...

Lyndon, here is the narrative you are referring to in the link you provided above:

Re:Thrust bearings

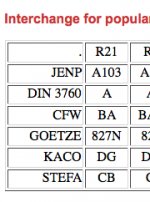

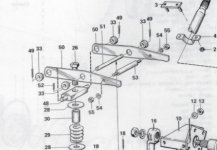

Most of the snow track OEM bearings and seals are SKF part numbers and are actual SKF parts. The number series has been changed in some cases, but can still be cross referenced by a baering supplier. The Thrust bearing that pushes the pulley halves closed is readily available and I use a Check republic copy from ZKL, it's a 51110A. This bearing appears to the naked eye to be the same on both sides, but actually one side is slightly smaller than the other. One side fits snugly on the Chive, over a collar. The other side pops in the cap and the race goes in between. The 'cap' is ST14A, the Bearing Bracket and the 2 parallel arms press against it. The top one has a zerk fitting, the lower one, on the other side of the variator has a hose barb, short hose and the Grease Zerk fitting that bolts on a bracket on the side of the engine compartment. The lower one rarely if ever goes bad, where as the upper one gets wet and will likely have to be replaced so you only have to buy one when you do a rebuild.

Here is a picture of mine...the lower bearing race looks to be part of the sheave /chive casting. I cleaned and scraped looking for separation between the two but couldn't find it. Also, when I put a wrench on the race the outer edge EASILY chipped off revealing raw metal which looked cast.

It looks like the bottom race is missing. No wonder the thrust bearing failed! Cast iron is not a very good bearing race...