at our leavenworth events i seen 2 shredded belts. both were at high rpms when they failed.

After much thought, I am leaning to the following scenario:

Cat sits most of 3 years with only the occasional ( like 2)low rpm run. belt is taking a set where it is wrapped for long periods of time motionless and tight. First real run this year was short and slow, mostly to check for binding and track belt tension. Then I really try to run her. Not red-line rpm, but near. Not for 5-10 minutes but for most of hour. belt separates and that's that. The cords in the belt were missing most of the rest of the belt.

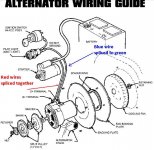

Checked tonight: pulley alignment: Center line of the two pulleys off about 2 mm. With vw's method of tensioning, that has to happen as the cl of the alternator pulley shifts with the shim stack. Both the damper and alt pulley are parallel. Alt pulley tight on shaft with no movement.

I will provide pix of mounting as I pull it just to check, I couldn't get good photo tonight

When I had her running before meow#1 I found that on hard pulls, keeping the rpm's way up kept the temp well within reasonable range. That engine speed may have been my undoing. I will see what the racing crowd uses for buggies/baja. Or perhaps I just need to run her more often (that's the idea) and change the belt yearly.

Besides changing the oil, anything else I need to do/check before next run? Can the excess heat affect the valve pushrod gap to where I need to go through them?

One more item for the spares kit. it's light and easy to store and I already had the required tools on board.

Just once I would like everything to just "as easy to drive as a car" rather than the "No Learning Curve Too Steep, No Pockets Too Deep"

CT