Snowcat Operations

Active member

Your brakes on the Track Master is located outside where your Bronze drive sprockets are.

Your brakes on the Track Master is located outside where your Bronze drive sprockets are.

Ok some more pics.

Fresh air unit. Bent but can be saved.

Because some people are excitable and forget certain things. Like not to lay the unit in front of a vehicle that runs and drives....

Have someone tig weld the holes. I had several panels replaced on mine.

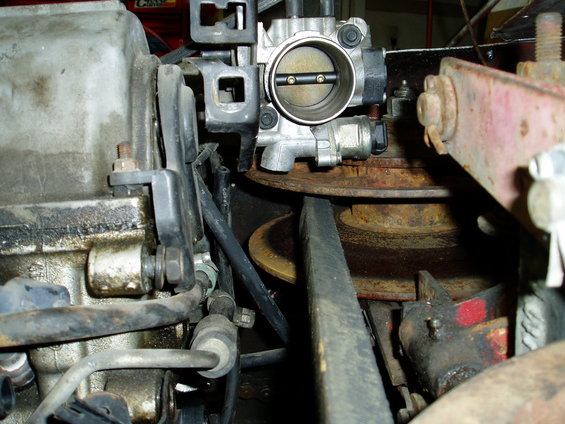

The Chrysler 2.2 Turbo is the small block Chevy of 4cyl's. This model is fuel injected, maked 150hp as it sits, and is easily modified safely for more. This motor makes real torque, not Honda style power in a narrow power band. For a few years in the late 80's it made more power and torque than the 360ci engines used in the full size Jeeps and the 318ci engines used in the Dodge trucks! It is very reliable as long as you do the required coolant changes etc. The most failure prone part is the distributer pick up assy. that is easily replaced and a spare can be kept in the glove box. I will have a real heater, and no more having to stop on long climbs or runs to let things cool down.

Plus all the benefits of modern fuel injection.