It’s tough to figure out where to start. My buddy Dave had wanted a steel track Tucker since I’ve known him. There was one for sale in Colton, NY by our camp several years ago, but I just thought he was nuts. So many parts = so many problems. (And still may be!!) I told him he was out of his mind and I wasn’t jumping on his loony wagon!

Five years pass and my kids are now at an age (7 & 9) where they can enjoy the winter outside on their own. Another buddy of ours sends me a link for a 5 man 252 Ski-dozer that is being sold by a religious camp up in Maine. Now this gets my wheels turning thinking that it would be great to utilize our camp all thru the winter, not just one special weekend trip in February to X-C ski and snowshoe. All of a sudden I’m the one that is looking around for snow cats. I try to find info on the Ski-dozer (which is out of my price range anyway) and cross paths with this forum. I proceed to lurk for a year just reading and taking it all in.

Dave must have planted the Tucker seed in my head all of those years ago because I’m being drawn back to them over & over. And with Cook’s only a state over, help’s not too far away. Then it happens. Stu (Mtn-Track) decides to show details of his Tucker: ‘An Old Cat’s Tail’. Well that was the kick in the ass I needed to really start looking. In December 2010 I buy from Stu the last two brand new 400 series pontoons made. Since he switched to the 1500 series tracks, he didn’t need them. Now realize I don’t even own a sno-cat of any type at this point. I’m just going on the assumption that whatever I find will probably need help on at least two of the pontoons.

Well that was the kick in the ass I needed to really start looking. In December 2010 I buy from Stu the last two brand new 400 series pontoons made. Since he switched to the 1500 series tracks, he didn’t need them. Now realize I don’t even own a sno-cat of any type at this point. I’m just going on the assumption that whatever I find will probably need help on at least two of the pontoons.

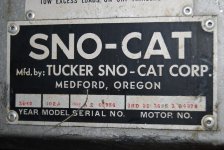

Forward to August 2011. I’ve been looking pretty hard for something in my price range that’s close. There is even a Tucker 442 in an old museum near me that I was working on acquiring, but the eccentric old coot will probably let the building collapse (literally) around it instead of selling it to be used again (we’ll see what happens with that in the future). I just happened to check Craig’s List for Tuckers one hot sunny day. Now I’m already thinking that I’m going to have to retrieve something from several states away if something is listed. A 1967 442 pops up in Groveland, MA only about 30 miles from where I work for $3500. I call and set up a time to go look at it. It’s dirty and has some issues, but for the money it’s ok. The previous owner bought a group of 4 as a package deal from Pat’s Peak in NH; three 442’s and one 443. He has a camp in Maine twenty miles off the main trail corridor. His family and the other 10 families that have camps in the area wanted the local snowmobile club (of which they were all members) to groom just once a month out to their location. The club wouldn’t do it. They bought an Alpine, but kept having troubles with it. So the Tuckers were purchased. One was immediately designated the primary groomer (the one I bought) and all of the best parts from the others were put on this machine so they could groom with limited issues. The 443 also received a total restore and was run for a few years, before someone stole it off the trail after they had left for the weekend. It still hasn’t been found. The 442 worked for a couple more years then in 2009 was brought back to Mass to be replaced with a Tucker 1000. So, when I bought it, it hadn’t run in a couple of years. But it did drive onto the trailer under its own power. So I wasn’t too worried about the old flathead.

(we’ll see what happens with that in the future). I just happened to check Craig’s List for Tuckers one hot sunny day. Now I’m already thinking that I’m going to have to retrieve something from several states away if something is listed. A 1967 442 pops up in Groveland, MA only about 30 miles from where I work for $3500. I call and set up a time to go look at it. It’s dirty and has some issues, but for the money it’s ok. The previous owner bought a group of 4 as a package deal from Pat’s Peak in NH; three 442’s and one 443. He has a camp in Maine twenty miles off the main trail corridor. His family and the other 10 families that have camps in the area wanted the local snowmobile club (of which they were all members) to groom just once a month out to their location. The club wouldn’t do it. They bought an Alpine, but kept having troubles with it. So the Tuckers were purchased. One was immediately designated the primary groomer (the one I bought) and all of the best parts from the others were put on this machine so they could groom with limited issues. The 443 also received a total restore and was run for a few years, before someone stole it off the trail after they had left for the weekend. It still hasn’t been found. The 442 worked for a couple more years then in 2009 was brought back to Mass to be replaced with a Tucker 1000. So, when I bought it, it hadn’t run in a couple of years. But it did drive onto the trailer under its own power. So I wasn’t too worried about the old flathead.

Five years pass and my kids are now at an age (7 & 9) where they can enjoy the winter outside on their own. Another buddy of ours sends me a link for a 5 man 252 Ski-dozer that is being sold by a religious camp up in Maine. Now this gets my wheels turning thinking that it would be great to utilize our camp all thru the winter, not just one special weekend trip in February to X-C ski and snowshoe. All of a sudden I’m the one that is looking around for snow cats. I try to find info on the Ski-dozer (which is out of my price range anyway) and cross paths with this forum. I proceed to lurk for a year just reading and taking it all in.

Dave must have planted the Tucker seed in my head all of those years ago because I’m being drawn back to them over & over. And with Cook’s only a state over, help’s not too far away. Then it happens. Stu (Mtn-Track) decides to show details of his Tucker: ‘An Old Cat’s Tail’.

Well that was the kick in the ass I needed to really start looking. In December 2010 I buy from Stu the last two brand new 400 series pontoons made. Since he switched to the 1500 series tracks, he didn’t need them. Now realize I don’t even own a sno-cat of any type at this point. I’m just going on the assumption that whatever I find will probably need help on at least two of the pontoons.

Well that was the kick in the ass I needed to really start looking. In December 2010 I buy from Stu the last two brand new 400 series pontoons made. Since he switched to the 1500 series tracks, he didn’t need them. Now realize I don’t even own a sno-cat of any type at this point. I’m just going on the assumption that whatever I find will probably need help on at least two of the pontoons. Forward to August 2011. I’ve been looking pretty hard for something in my price range that’s close. There is even a Tucker 442 in an old museum near me that I was working on acquiring, but the eccentric old coot will probably let the building collapse (literally) around it instead of selling it to be used again

(we’ll see what happens with that in the future). I just happened to check Craig’s List for Tuckers one hot sunny day. Now I’m already thinking that I’m going to have to retrieve something from several states away if something is listed. A 1967 442 pops up in Groveland, MA only about 30 miles from where I work for $3500. I call and set up a time to go look at it. It’s dirty and has some issues, but for the money it’s ok. The previous owner bought a group of 4 as a package deal from Pat’s Peak in NH; three 442’s and one 443. He has a camp in Maine twenty miles off the main trail corridor. His family and the other 10 families that have camps in the area wanted the local snowmobile club (of which they were all members) to groom just once a month out to their location. The club wouldn’t do it. They bought an Alpine, but kept having troubles with it. So the Tuckers were purchased. One was immediately designated the primary groomer (the one I bought) and all of the best parts from the others were put on this machine so they could groom with limited issues. The 443 also received a total restore and was run for a few years, before someone stole it off the trail after they had left for the weekend. It still hasn’t been found. The 442 worked for a couple more years then in 2009 was brought back to Mass to be replaced with a Tucker 1000. So, when I bought it, it hadn’t run in a couple of years. But it did drive onto the trailer under its own power. So I wasn’t too worried about the old flathead.

(we’ll see what happens with that in the future). I just happened to check Craig’s List for Tuckers one hot sunny day. Now I’m already thinking that I’m going to have to retrieve something from several states away if something is listed. A 1967 442 pops up in Groveland, MA only about 30 miles from where I work for $3500. I call and set up a time to go look at it. It’s dirty and has some issues, but for the money it’s ok. The previous owner bought a group of 4 as a package deal from Pat’s Peak in NH; three 442’s and one 443. He has a camp in Maine twenty miles off the main trail corridor. His family and the other 10 families that have camps in the area wanted the local snowmobile club (of which they were all members) to groom just once a month out to their location. The club wouldn’t do it. They bought an Alpine, but kept having troubles with it. So the Tuckers were purchased. One was immediately designated the primary groomer (the one I bought) and all of the best parts from the others were put on this machine so they could groom with limited issues. The 443 also received a total restore and was run for a few years, before someone stole it off the trail after they had left for the weekend. It still hasn’t been found. The 442 worked for a couple more years then in 2009 was brought back to Mass to be replaced with a Tucker 1000. So, when I bought it, it hadn’t run in a couple of years. But it did drive onto the trailer under its own power. So I wasn’t too worried about the old flathead.

Once the bad gas was out, I dumped in 2 gallons of acetone and sloshed it around a couple of times a day for 2 days. I drained that out, dumped in 5 fresh gallons w/ some Sea Foam added, and primed the fuel pump and carb. Hit the key and after about three seconds it fires up and goes into a rough idle (because of the mystery oil). She smokes for a few minutes, clears out, and then purrs like a kitten. I was psyched!

Once the bad gas was out, I dumped in 2 gallons of acetone and sloshed it around a couple of times a day for 2 days. I drained that out, dumped in 5 fresh gallons w/ some Sea Foam added, and primed the fuel pump and carb. Hit the key and after about three seconds it fires up and goes into a rough idle (because of the mystery oil). She smokes for a few minutes, clears out, and then purrs like a kitten. I was psyched!

I go back to the first one and proceed to give it another good round of beatings and it finally gives up.

I go back to the first one and proceed to give it another good round of beatings and it finally gives up.

One third of my connectors are worn, but the bar is flat, which means the outside to outside distance on the pins is 3 1/2 inches. One third have had the bars arched slightly to make the distance roughly 3 7/16th inches to compensate for wear and the last third are arched slightly more to measure around 3 3/8th inches.

One third of my connectors are worn, but the bar is flat, which means the outside to outside distance on the pins is 3 1/2 inches. One third have had the bars arched slightly to make the distance roughly 3 7/16th inches to compensate for wear and the last third are arched slightly more to measure around 3 3/8th inches.