The Tourist

Banned

One of the misconceptions I'd like to clear up is my view of tools and alloys. Granted, I like to have good equipment. When it comes to knives and protecting my miserable hide, I want the best. Chefs want the best, too.

But what is forgotten is that I live in Wisconsin. Watch a Packers' game sometime and you'll see as much blaze orange as you do Green n' Gold. Around here deer hunting is a religious holiday. I've seen clients with whitetail tattoos. We have children here who have never eaten meat from a store.

They also need the best, and most can't afford it. In fact, most tinkers I know do pro bono work for subsistance hunters.

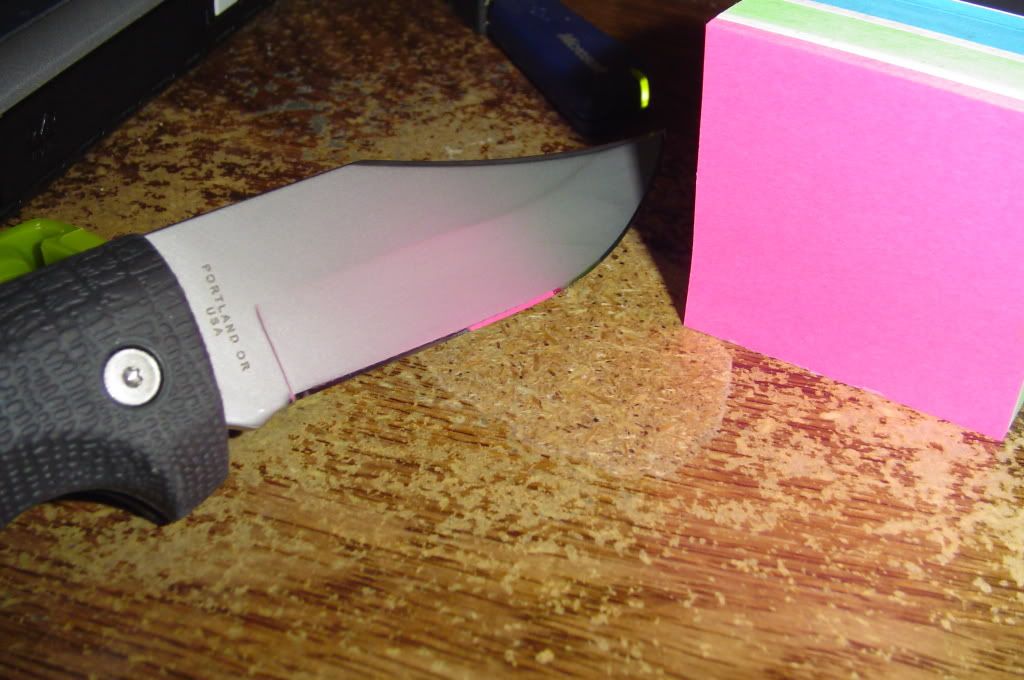

A few days ago I needed something out of my wife's SUV glovebox, and I found a "truck knife" I had given her years ago for emergencies. I was astounded to find it still had its original edge. To demonstrate the overall issue discussed here, I decided to sharpen that knife as I would for a Wisconsin deer hunter.

The knife is an older Gerber Gator. While newer models are crafted from 154-CM (the same alloy used in Emerson CQC-7s) my wife's example is probably some form of 420. I hate to use the word 'mundane,' but 420 and its variants are used in a lot of knives produced for under 20 dollars.

In fact, the present Gator model using 154-CM is listed at $29.95, and I can get them for half that price.

My wife's example is a "knife" knife. Nothing more. And the perfect candidate.

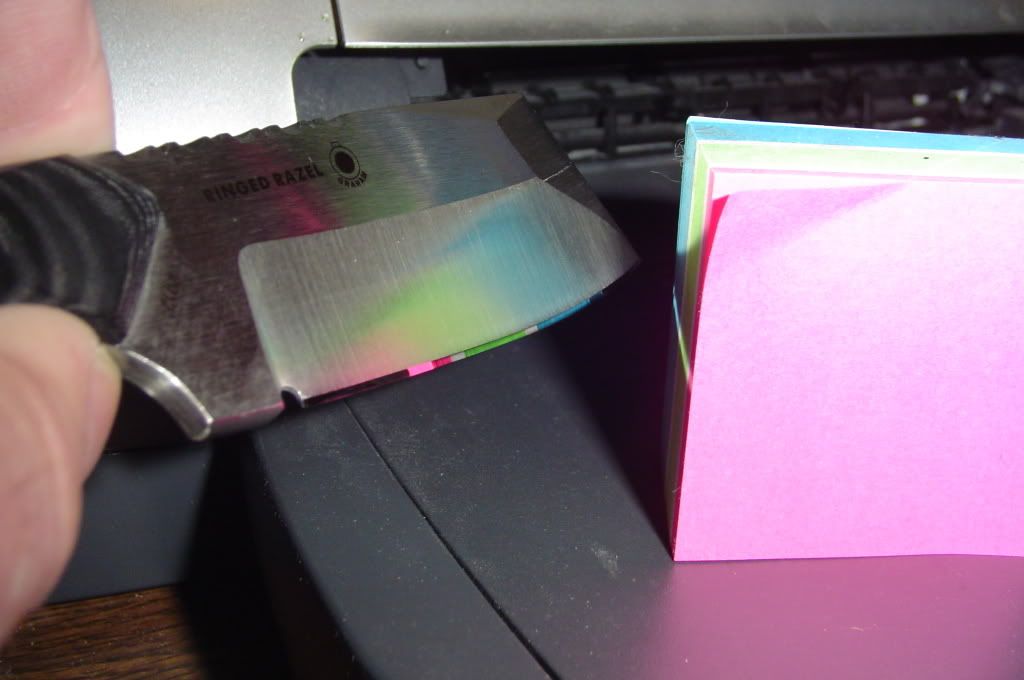

While the Gerber now resides in the freezer for the start of its polishing, I took a picture of it as the bevel was trued to a uniform shape. Any spooky sharp edge must be corrected during this initial phase or the remaining work is all up hill.

This knife was as crooked as a warped boomerang. Both sides were not only of differing angles, but the edge near the choil was different from the tip. Obviously an apprentice sharpener was on duty that day. It took over 20 minutes just to block in the correct uniform bevel.

I'll report more as the work developes.

But what is forgotten is that I live in Wisconsin. Watch a Packers' game sometime and you'll see as much blaze orange as you do Green n' Gold. Around here deer hunting is a religious holiday. I've seen clients with whitetail tattoos. We have children here who have never eaten meat from a store.

They also need the best, and most can't afford it. In fact, most tinkers I know do pro bono work for subsistance hunters.

A few days ago I needed something out of my wife's SUV glovebox, and I found a "truck knife" I had given her years ago for emergencies. I was astounded to find it still had its original edge. To demonstrate the overall issue discussed here, I decided to sharpen that knife as I would for a Wisconsin deer hunter.

The knife is an older Gerber Gator. While newer models are crafted from 154-CM (the same alloy used in Emerson CQC-7s) my wife's example is probably some form of 420. I hate to use the word 'mundane,' but 420 and its variants are used in a lot of knives produced for under 20 dollars.

In fact, the present Gator model using 154-CM is listed at $29.95, and I can get them for half that price.

My wife's example is a "knife" knife. Nothing more. And the perfect candidate.

While the Gerber now resides in the freezer for the start of its polishing, I took a picture of it as the bevel was trued to a uniform shape. Any spooky sharp edge must be corrected during this initial phase or the remaining work is all up hill.

This knife was as crooked as a warped boomerang. Both sides were not only of differing angles, but the edge near the choil was different from the tip. Obviously an apprentice sharpener was on duty that day. It took over 20 minutes just to block in the correct uniform bevel.

I'll report more as the work developes.