-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

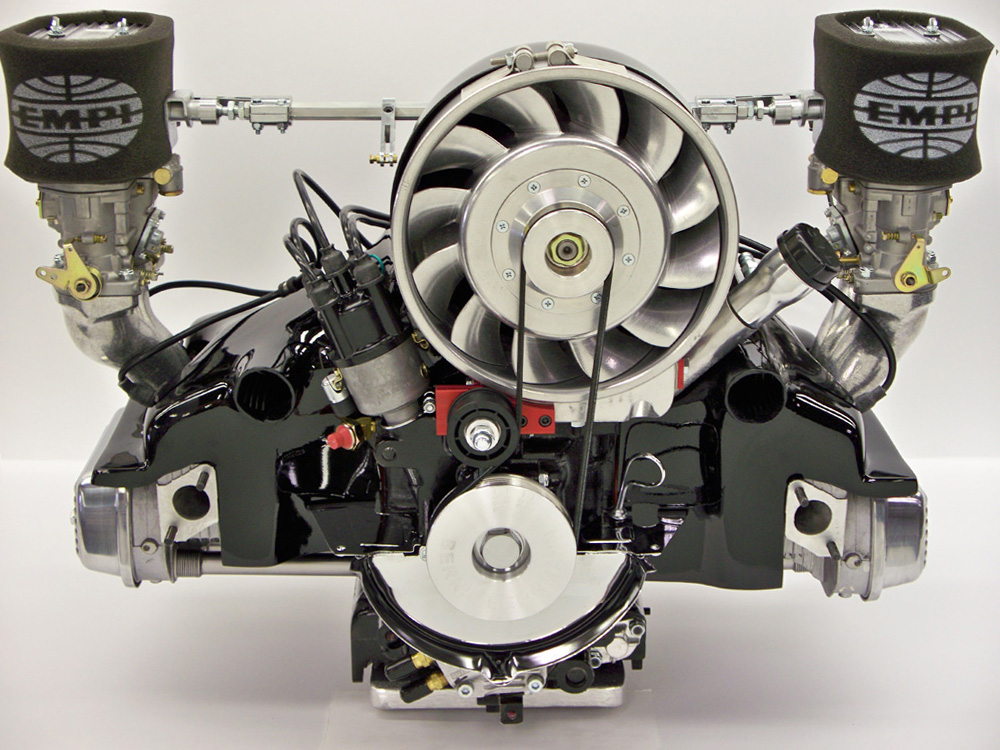

snow trac air horn

- Thread starter JimVT

- Start date

Snowtrac Nome

member formerly known as dds

vw didn't use any thing they had enough fresh air running over the top of the motor and an open belly unlike the snow trac.

Snowtrac Nome

member formerly known as dds

Lyndon would know better I believe it was all forced induction from luvers on the side in to the engine compartment. I remember hearing long periods of idle time while not moving could over heat them on hot days.

VW has a sealed engine compartment so the fan had to suck in cool air from outside louvers, Later Snow Tracs had a metal box bolted to the back side of the fan shroud to seal out the rest of the engine compartment and suck in air from the louvers on the hood. You have the later "doghouse" fan shroud (which is a better setup to keep #3 cyl. cooler) but you need to make a custom box to draw in cool air from hood louvers. Hope that makes sense.....

Chris

Chris

Lyndon

Bronze Member

Bugs, Busses, Karman Ghia's, all had sealed engine compartments.

http://www.forumsforums.com/3_9/showthread.php?t=3895

There was elaborate tin and rubber seals so that air came in above the engine, got sucked thru the engine, and exhausted out the bottom.

Some not so observant ST4 owners discarded their Air intake induction horn. This usually ends up destroying the engine. They put it there for a reason.

http://www.forumsforums.com/3_9/showthread.php?t=3895

There was elaborate tin and rubber seals so that air came in above the engine, got sucked thru the engine, and exhausted out the bottom.

Some not so observant ST4 owners discarded their Air intake induction horn. This usually ends up destroying the engine. They put it there for a reason.

Snowtrac Nome

member formerly known as dds

Lyndon mine must be the odd duck it has no oil temp gauge or hole in the dash for one I have seen the machines with them but mine had none installed I did add a CHT gauge which is better than an oil temp gauge.The heating, or overheating problem was serious enough that Westermaskiner installed an oil temperature meter on every machine they ever built, it was not an option.

Lyndon

Bronze Member

Yours would be a 'first' as the hundreds of machines I looked at, owned, and worked on all had them. They are shown on even the earliest service manuals. They used a 'dip-stick' sender which was only used as an option on early VW Products,.. not standard equipment. Some outfit in California still sells a replacement dipstick temperature sender. It and the Guage were VDO. In the earlier article, with the link, the final permanent "Fix", relied heavily on setting the Fuel/Air Radio with an engine gas analyzer. Most aircooled aircraft have temp senders in the manifolds or on each cylinder and one adjust the Fuel/Air Ratio as well as the Spark to keep from over heating. The engine compartment ran so hot in ST4's that it often burnt up the Fan Belt, or started damaging the Variator belt as well as cooking various gaskets and threatening the Coil and associated wiring. The "Rulle of Thumb" is: If you Can't hold the Dip Stick, it's too Hot! Bug engines like to run Hot, but not too hot. Also the Death of many VW powered machines was the over heating led to a rubber fuel line coming off in the engine compartment, followed by a disasterous fire. There was an FAA ST4, just north of you, in Kotzebue that I looked at and I believe that is what caused it to burn up,... removal of the air induction horn. Once the engine caught on fire, it set one of the Big wheels in front of fire which in turn burned a hole in the fender, big mess! It sat there at the Post Office, dead, for a year or so then a guy who owned a Mine way inland bought it for parts. He had several machines at the mine, he liked them as they could be fit in the cargo door of a early prop job, like a DC3 or DC6. I dread to see what they look like today! It was not Red Dog, some name that started with a 'L' I believe. Probably NOT on Mapquest.

Snowtrac Nome

member formerly known as dds

I'm working on one for Vernon Atkinson from bering sea gold his has the oil temo gauge he also has the original hand crank which I intend to reproduce.

Snowtrac Nome

member formerly known as dds

Jim I would like to see how it works I would love one thet are so expensive I don't want to spend the money till I find one that will work

Lyndon

Bronze Member

YES! that looks like a "Self Supporting", much like the Porsche starters, only gear reduction. This would also eliminate the problem with the bushing that is in the bell housing. A 6 volt had a huge hole and a big bushing, the later, and in the case of Snow Trac, much later, 12Volt has a smaller hole in the bell housing, and a smaller bushing for the smaller 12V shaft. Aftermarket outfits made an adapter bushing, brass, like the OEM stuff, that fit the larger 6Volt Bell Housing, but was milled out for a smaller 12V shaft. VW changed to 12 Volt in 1966. That is the year of the 1300 which was only manufactured for one year. But VW Industrial Motors came equipped for 6 volt starters much later. I don't think they actually shipped them out with real 12Volt starters and generators for another 3 years. What Snow Trac did was use a 6 Volt starter, re-fit it with a 12 Volt solenoid, and leave the original 6 volt flywheel. They also sported the little, small diameter 12 Volt generator. About one year of VW bus, and maybe 8 years of Porsche use this small diameter 12 Volt generator that will fit on the Oil pedistal of a 6 volt engine.

This adaptation of the starter looks interesting, I'll be anxious to see how it workls out. It would be an outstanding solution to a long standing problem with ST4's.

This adaptation of the starter looks interesting, I'll be anxious to see how it workls out. It would be an outstanding solution to a long standing problem with ST4's.

JimVT

Bronze Member

It fits using the last hole on the face plate. the solenoid isn't straight up like orginal but leaning towards the tower. I have 3/4 inch clearance between the tower and starter.

original wv starter mounts are used no tabs on bolts. Connection for starter wires are on the inside side of starter now.

if you need more pictures I can get some.

original wv starter mounts are used no tabs on bolts. Connection for starter wires are on the inside side of starter now.

if you need more pictures I can get some.

Snowtrac Nome

member formerly known as dds

that looks good I'm going to have to look into one.

ChocoCat

New member

But for cooling there is Raby's DTM (down the middle) replacing the age old, highly in need of redesign doghouse .

Unfortunately out of stock currently.

http://vwparts.aircooled.net/Raby-s-Aircooled-Technology-Type-1-DTM-11001-p/11001.htm

Raby's Aircooled Technology Type 1 DTM (Down The Middle) Fan Shroud Kit,11001 is the finest system for the Type 1 engine! Jake Raby used hundreds of gallons of fuel on his dyno to develop the finest cooling system the type 1 engine has ever seen! This is a legendary shroud which is the only cooling system available for the VW Type 1 that effectively and efficiently routes cooling air to all 4 cylinders equally and is both dyno, race and street proven to do so! This system has seen hundreds of hours of dynamometer testing to enhance the airflow to the cylinders that need it most! Currently no other cooling system currently available can even come close to the DTM in properly cooling a type 1 engine. The DTM compares to a stock doghouse system the way a doghouse system compares to the in shroud system, it really is that good!This system will fit any upright type 1 engine.

Unfortunately out of stock currently.

http://vwparts.aircooled.net/Raby-s-Aircooled-Technology-Type-1-DTM-11001-p/11001.htm

Sno-Surfer

Well-known member

I've never seen that Raby set up before. I'd be curious if anyone has used it and if they noticed a difference.

That air horn looks Heavy Duty!! I made one as well by just bending sheet metal and riveting the ends together. It works fine and is light weight. I didn't have the dog house fan shroud to work around.

Looks good though.

That air horn looks Heavy Duty!! I made one as well by just bending sheet metal and riveting the ends together. It works fine and is light weight. I didn't have the dog house fan shroud to work around.

Looks good though.