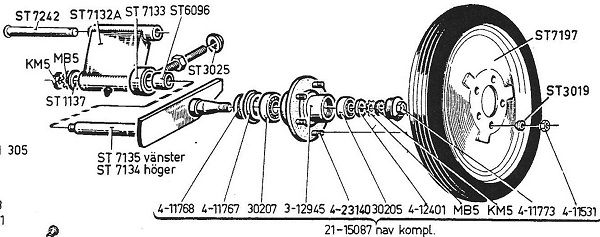

The right side rear wheel of the ST was so loose it was allowing the track, grousers to tear up the body. From reading here it was pretty obvious that the old bushings were shot.

First mistake: I decided that I would have enough slack that I could loosen everything up and remove the rear wheel without breaking the track. After all is said and done, it would have been better to just break the track and get it out of the way. Getting the tire off, not bad, getting it back on ...

So, tire is off. Found that one of the ears that holds the top pin of the st7132 bracket was damaged. No problem says I, pull the cotter key and remove the pin.

Nope

OK, tap it a few times with a hammer and squirt some penetrating oil.

Nope

Put the portapower ram between the frame and the end of the pin to push it out.

Nope

Heat with a torch while the ram is still in place.

Nope

repeat the above plus a few other things.

Nope

Use a thin blade on the sawz-all and use the space between the bracket and the ears to cut the pin on both sides.

Take to friends 80 Ton press to get rid of cut pin.

Nope

Wound up carefully center drilling the old pin out. Still had the slit the remains and use a chisel to break it free.

more in replys...

First mistake: I decided that I would have enough slack that I could loosen everything up and remove the rear wheel without breaking the track. After all is said and done, it would have been better to just break the track and get it out of the way. Getting the tire off, not bad, getting it back on ...

So, tire is off. Found that one of the ears that holds the top pin of the st7132 bracket was damaged. No problem says I, pull the cotter key and remove the pin.

Nope

OK, tap it a few times with a hammer and squirt some penetrating oil.

Nope

Put the portapower ram between the frame and the end of the pin to push it out.

Nope

Heat with a torch while the ram is still in place.

Nope

repeat the above plus a few other things.

Nope

Use a thin blade on the sawz-all and use the space between the bracket and the ears to cut the pin on both sides.

Take to friends 80 Ton press to get rid of cut pin.

Nope

Wound up carefully center drilling the old pin out. Still had the slit the remains and use a chisel to break it free.

more in replys...