utahwilson

New member

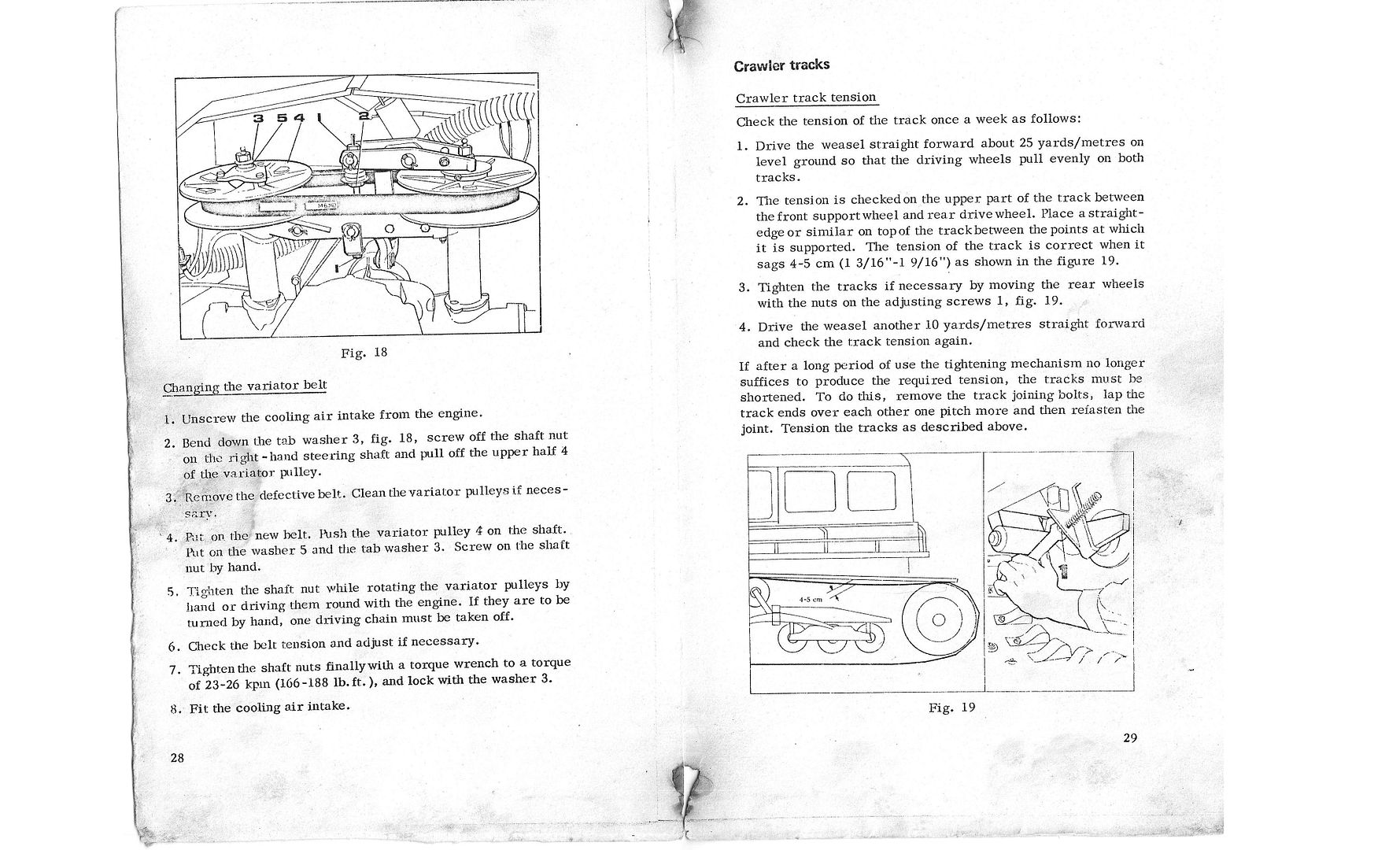

I finally got my cat back from peterson equipment. Looks great. However, on driving around the yard the tracks slap the underside of the fenders. Is there a guide for how tight the tracks should be?

Also, can anyone recommend a duel port carb with choke. I have a weber after market carb with no choke and am having a heck of a time starting the cat with no choke.

thanks

-K

Also, can anyone recommend a duel port carb with choke. I have a weber after market carb with no choke and am having a heck of a time starting the cat with no choke.

thanks

-K

Not sure how she feels about it. Its a dual port motor. I will check out craft.com. I need to figure out the track thing though. Bugs the heck out of me when the track slaps up against the front fender. Taking snowcat out on Friday with nephews. I will play around with the adjustment then. thanks for the advice

Not sure how she feels about it. Its a dual port motor. I will check out craft.com. I need to figure out the track thing though. Bugs the heck out of me when the track slaps up against the front fender. Taking snowcat out on Friday with nephews. I will play around with the adjustment then. thanks for the advice