Is there a general rule about how much tension, or the correct amount of sag for determining proper track tension?

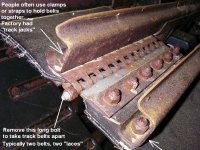

These are new home built tracks with a new drive sprocket and the front idler wheel is bolted all the back to allow the most slack possible. I have 55 grousers on each track on 4" centers.

With the tracks off the ground, the center two boggies have about 1 inch of space between the bottom of the tire and tire guide(I would call this the sag in the track).

I can only pick the top of the track up off the center boggies about 3 inches with arm strength. And I can only slowly roll the track by hand using all my strength (its about 10 deg in my shop and the belting is pretty stiff).

I can see about 1/4" gap between the new plastic drive sprocket and the grouser tire guide that will soon wear in allowing the grouser tire guide to fit snug to the sprocket so that should give me a 1/4" less tension when I get more miles on them (about 5 miles total so far). I think the stretch is already out of this belting because it was used on a conveyor for 7 years.

These are new home built tracks with a new drive sprocket and the front idler wheel is bolted all the back to allow the most slack possible. I have 55 grousers on each track on 4" centers.

With the tracks off the ground, the center two boggies have about 1 inch of space between the bottom of the tire and tire guide(I would call this the sag in the track).

I can only pick the top of the track up off the center boggies about 3 inches with arm strength. And I can only slowly roll the track by hand using all my strength (its about 10 deg in my shop and the belting is pretty stiff).

I can see about 1/4" gap between the new plastic drive sprocket and the grouser tire guide that will soon wear in allowing the grouser tire guide to fit snug to the sprocket so that should give me a 1/4" less tension when I get more miles on them (about 5 miles total so far). I think the stretch is already out of this belting because it was used on a conveyor for 7 years.